Industry 4.0 is a global trend that requires organizations to innovate on their services, products, and processes and incorporate automation into their supply chain if they want to stay competitive.

South Korea has ten robots per 1,000 workers and Japan has five per 1,000. These are the countries leading the way, followed by European countries. Mexico has fallen behind, but it still has time to secure a position in the region.

Time is of the essence. The window of opportunity to join the new trend is a period of approximately five to ten years, says Abraham Tijerina Priego, leader of Business Developers at the Research and Graduate Office of the School of Engineering and Sciences at Tec de Monterrey. This university aims to become a lifelong ally to companies so that they can ride this new wave.

What is industry 4.0

After the pandemic, companies will need to redesign their road maps and ask themselves about the what, where, and why of their operating models to position themselves in the future, when the physical world merges with the digital one.

Organizations will have to make big changes that will need the impartial and expert view of academia. But why? Universities are the places where you can experiment and fail as many times as necessary. It’s where leaders are made and where they acquire the knowledge that will translate into marketable skills.

The ABC’s for industry 4.0

The World Economic Forum has defined the following features of Industry 4.0 that will transform economies, jobs, and society itself:

- Artificial intelligence (AI) will identify data patterns in real-time, which will help predict trends and inform decision-making.

- Work teams are part of a network, but they have the autonomy to decide the best way to optimize performance (without neglecting the corporation’s objectives).

- Virtual reality will be part of our daily lives, merging physical and digital worlds together. This will create business opportunities for companies and individuals to invest in digital currencies, goods, and services.

- Companies will become more scientific, in the sense that they will set up their own research centers where they test marketable models or create partnerships with academia to expand their possibilities.

- The addition of sensors and greater connectivity will lead us to the Internet of Things, an age when static objects will be smart and will streamline industrial processes.

- Automation. Robots will replace workers performing manual tasks (such as assembly, material handling, packaging, and welding).

These changes imply enormous challenges. For example, automation will have an uncertain effect because it will involve cutting staff and reducing salaries, but it will also increase the productivity of companies, which will then have a greater capacity to expand and create new jobs.

A lifelong relationship with the Tec

Abraham Tijerina Priego, with more than 30 years in the industry, was coordinator of the Nuevo León 4.0 citizen initiative for three and a half years and is currently the leader of the Subcommittee on Innovation, Technology, and Digital Transformation of the Nuevo León Council for Strategic Planning.

He joined Tec de Monterrey in December 2021 to strengthen the relationship between the university and industry.

“We put forward the Corporate Outreach Program in which large companies that are already linked to Tec de Monterrey join forces to conduct joint research and development in the creation of new products, processes, and services,” he says.

In this initiative, the Tec is the one approaching companies to jointly define the existing areas of opportunity and draw up a road map for short-, medium-, and long-term collaboration.

“We opted for a more proactive model that first seeks to understand organizations before trying to sell them on the solution,” he says.

The Tec’s idea is to provide lifelong support to companies in a permanent and continuous relationship.

“In Mexico, we’re behind in the areas of Digital Transformation and Industry 4.0, so we have to get on board soon or we’ll lose competitiveness. We have a window of opportunity of approximately five to ten years to make the transformation in key product sectors and maintain that competitiveness in the region.”

Pilot tests in Nuevo León

Nuevo León and the northern states are perfect for this industry. They naturally have an interest in everything associated with high-value manufacturing because they have the United States, the largest consumer market in the world, as their neighbor.

In Nuevo León, the academia-industry collaboration has already begun —regardless of little support and limited public legislation to consolidate the relationship— and it has been embedded in social capitalism for a few years now:

“Companies are committed to their social environment. They’re interested in having innovative staff who are educated, specialized, and healthy, with decent housing, and who can comfortably travel to work and have time for leisure activities,” says the expert.

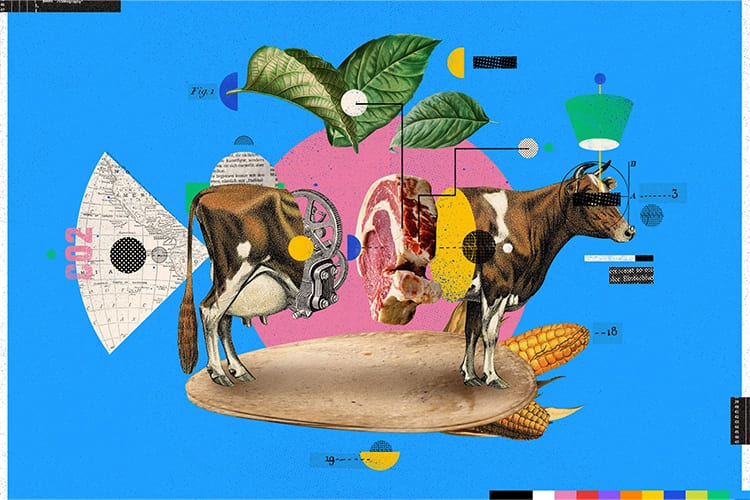

The Tec has a presence in almost all of Mexico. Its impact and contribution to the technical transformation of partner companies could be significant. It’s a matter of identifying the driving forces and strengths of each region: in some places, it may be fishing; in others, it’s livestock; or it could be aeronautics somewhere else.

By getting involved in the solutions to real problems, teachers and researchers become very valuable resources because they not only contribute to the competitiveness of companies but also share practical and current knowledge with their students.

There is now talk of a 5.0 or super-intelligent society in which technology will not only generate wealth and resources but also be at the service of society for the greater wellbeing of all its citizens. Are we ready for that?