By Carlos A. Huerta-Aguilar, Eduardo Daniel Tecuapa-Flores, Carlos Pérez-Pliego and Pandiyan Thangarasu

Phenol is a substance found in many products we use, including resins, synthetic fibers, disinfectants, antiseptics, such as mouthwashes and throat lozenges.

Phenol is a highly toxic compound often found in wastewater from the chemical, pharmaceutical, and plastics industries. It’s hard to break down, harmful to living organisms, and stubbornly resistant to traditional water treatment methods.

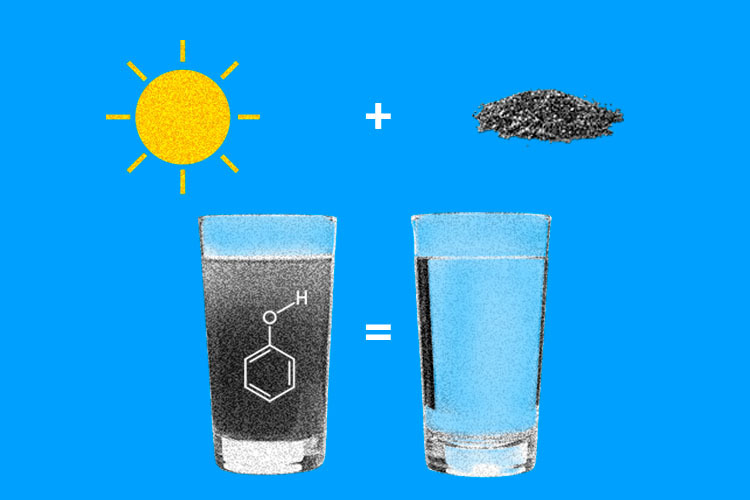

Now, a team of researchers from Tecnológico de Monterrey and the National Autonomous University of Mexico (UNAM) has designed an improved Photo-Fenton process that uses light, iron complexes, and carefully tuned chemistry to degrade phenol more sustainably.

Experimental procedure with light and iron

The process we propose is called Photo-Fenton, and it is based on the classic Fenton reaction—discovered more than a century ago—that relies on iron ions (Fe²⁺) and hydrogen peroxide (H₂O₂) to generate hydroxyl radicals (•OH), which aggressively attack organic pollutants.

The catch is that it only works under very acidic conditions (around pH 3), which limits its real-world applications. In this new study, researchers tested modified iron complexes that stabilize the oxidation states of iron, allowing the process to work under milder conditions—even at neutral pH.

By combining this with ultraviolet (UV) light exposure, they enhanced the system’s reactivity and efficiency, resulting in a more powerful and adaptable version of the original method.

The standout finding is that, under certain conditions, phenol degradation exceeded 99% in just 30 minutes, especially when the system was activated with UV light.

Experimental procedure with light and iron

The experimental setup included a custom quartz photoreactor equipped with a UV mercury lamp (254 nm). This simulates realistic treatment conditions and measures the contribution of UV light in the degradation process.

One of the most effective methods involved using iron salts (Fe²⁺), though they had a drawback: they only worked well in highly acidic environments. In contrast, other iron compounds, such as [Fe(terpy)Cl₃] and K₃[Fe(CN)₆], maintained their effectiveness even under milder conditions, helping to avoid issues like the formation of solid iron residues.

Of these two iron compounds, the latter stood out for its strong performance at pH levels close to neutral—that is, similar to those of regular water. And while its name might raise concerns—since it contains cyanide—it’s important to clarify that in this case the compound is safe, highly stable, and poses no risk under the conditions of the experiment.

This work shows how careful molecular design and light-driven chemistry could revolutionize environmental cleanup.

The ability to operate near neutral pH and with lower chemical doses opens the door to real-world applications such as modular treatment units, solar-powered purification systems, and affordable solutions for rural areas or industrial sites.

Demand for clean water

Rising demand for clean water and tougher environmental standards are driving an urgent need for adaptable, eco-friendly treatment solutions.

Recent advances in photoelectrochemical water treatment, nanocatalysis, and solar-driven purification all point in the same direction: the future lies in energy-efficient systems with low environmental impact that can easily integrate into existing infrastructure.

Building on this study, the next steps will explore scaling up modified Fenton systems powered by sunlight, using iron complexes derived from industrial waste, and integrating these treatments into decentralized purification modules.

These efforts align with the principles of the circular economy and the push to democratize access to clean water—especially in vulnerable, resource-limited regions.

Editor’s note: This research reflects a collaboration between Tec de Monterrey and UNAM, in line with ongoing work on green catalysis and sustainable water treatment. International partners include University College London, UT Austin, and the University of Calgary, focusing on hydrogen production, circular waste flows, and optimizing the Water-Energy-Food Nexus.

.

References

- Ahuja, D. et al. (2007). Modified Fenton reaction for trichlorophenol dechlorination. Chemosphere.

- Babuponnusami, A. & Muthukumar, K. (2014). Review on Fenton and modified Fenton for wastewater treatment. J. Environ. Chem. Eng.

- Bautista, P. et al. (2008). Application of Fenton oxidation to industrial wastewater. J. Chem. Tech. Biotech.

- De Laat, J. et al. (2004). Effect of anions on decomposition of H₂O₂ in Fenton systems. Chemosphere.

- Kavitha, V., & Palanivelu, K. (2004). Role of Fe²⁺ in Fenton and Photo-Fenton for phenol. Chemosphere.

- Li, Y. et al. (2005). Kinetics of chelate-based Fenton reactions. Environ. Eng. Sci.

- Zazo, J. A. et al. (2005). Chemical pathway of phenol oxidation via Fenton. Environ. Sci. Technol.

- Zhang, F. et al. (2018). Biochar-catalyzed ozonation of phenol in wastewater. J. Environ. Mgmt.

Autores

Carlos A. Huerta-Aguilar is an Assistant Professor at Tecnológico de Monterrey. He holds a Ph.D. in Environmental Engineering and specializes in solar-driven catalysis, waste valorization, and circular chemistry. He has completed postdoctoral fellowships at Stanford University and Texas A&M, and co-leads international projects on hydrogen, biogas, and agrivoltaics.

Pandiyan Thangarasu is a senior researcher and professor at the Faculty of Chemistry, UNAM. His work focuses on coordination chemistry, catalytic systems, and green remediation strategies. He is widely recognized for his contributions to metal-organic complexes and advanced oxidation technologies, with collaborations across Latin America and Asia.

Eduardo Daniel Tecuapa Flores earned a Ph.D. in Environmental Engineering from UNAM, where his research centers on developing new nanomaterials for environmental applications. He carried out two research stays at the Indian Institute of Technology, Ropar, and is currently a postdoctoral fellow at the Polytechnic University of the Valley of Mexico and UNAM, supported by SECIHTI.

Carlos Pérez Pliego holds a degree in Industrial Biochemical Engineering from Universidad Autónoma Metropolitana, Iztapalapa, and a Master’s in Environmental Engineering from UNAM. He currently works as Operations and Maintenance Supervisor at Aryeh Ingeniería del Agua S.A. de C.V.