Inside an industrial plant, an engineering student designs, tweaks, and validates a fiber extrusion machine—capable of shaping materials by forcing them through a nozzle or mold—to pitch the proposal directly to the company’s executive leadership.

It might seem like a real-life scenario, but this factory exists in a virtual space, and its CEO is a business-savvy avatar powered by artificial intelligence. Through this digital simulation, students gain advanced manufacturing and product development technical knowledge and build soft skills like effective communication and strategic decision-making.

That’s the essence of the VR FrED Laboratory Powered by Large Language Models—a cutting-edge immersive learning environment developed by researchers from the Massachusetts Institute of Technology (MIT) and Tec de Monterrey. The project blends advanced technologies such as virtual reality and artificial intelligence with game-based learning strategies to create a rich educational experience.

Pedro Ponce, a researcher at the Institute of Advanced Materials for Sustainable Manufacturing (IAMSM) at Tec de Monterrey, explains that this virtual lab is a project that brings together research, education, and real-world industrial application.

The platform is designed with personalized learning in mind. After completing an initial questionnaire, the system adapts its content to match each student’s needs and learning profile.

Instead of issuing traditional grades, the platform uses a system of achievements and rewards—similar to what you’d find in apps like Duolingo—to keep students motivated, based on how much they’ve learned. These achievements can even be shared on social media as digital badges.

“This lab adapts to your personality and learning style,” says Ponce. “What we’re aiming for, from an educational standpoint, is to create a space where students feel free to explore knowledge, without constantly being watched by a progress bar.”

The Virtual Lab for Advanced Manufacturing

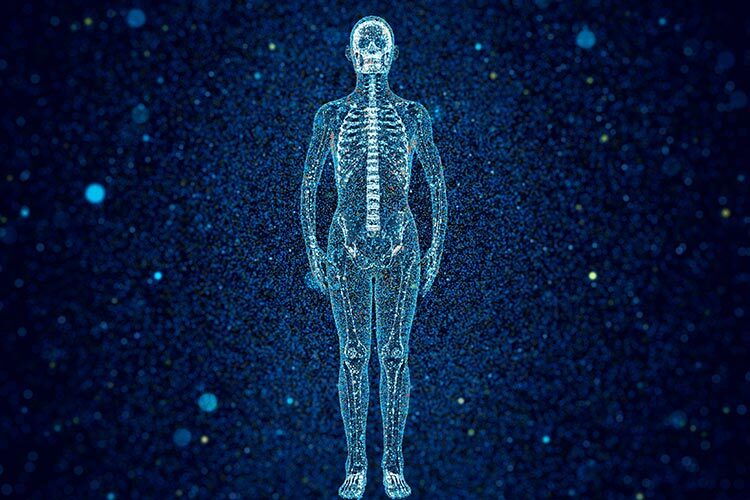

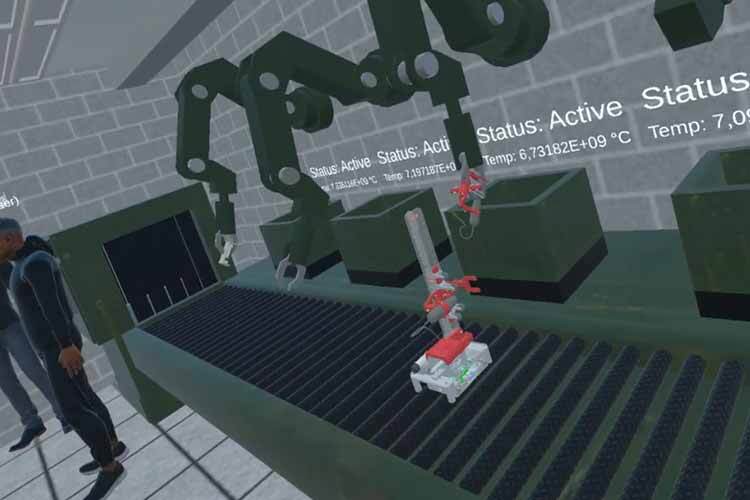

The virtual space operates as a simulated industrial plant, with workstations and production lines equipped with robotic arms. Students can navigate through the factory, interact with machinery, and adjust variables affecting the plant and its supply chain. In short, they simulate the process, collect operational data, and use it to optimize the production line.

The experience walks students through every product development phase—from the initial idea to technical simulation, economic evaluation, and final validation, factoring in raw material sourcing, waste management, and logistics. As part of their training, students work with algorithms focused on factory improvements, such as optimizing manufacturing processes or assessing equipment conditions like performance and lifespan.

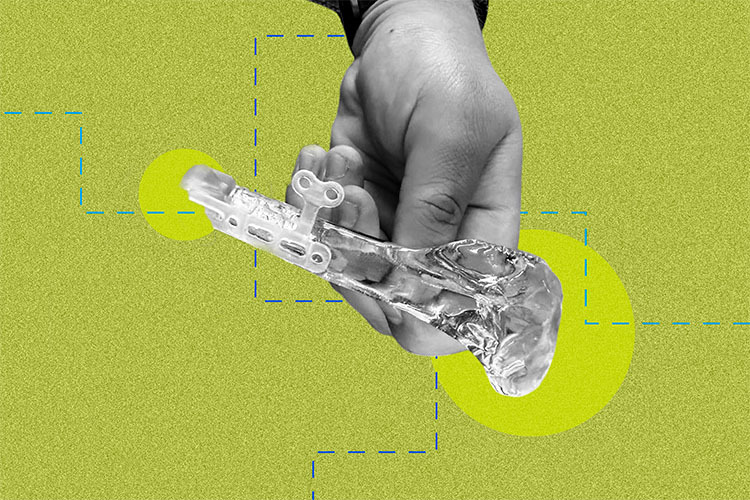

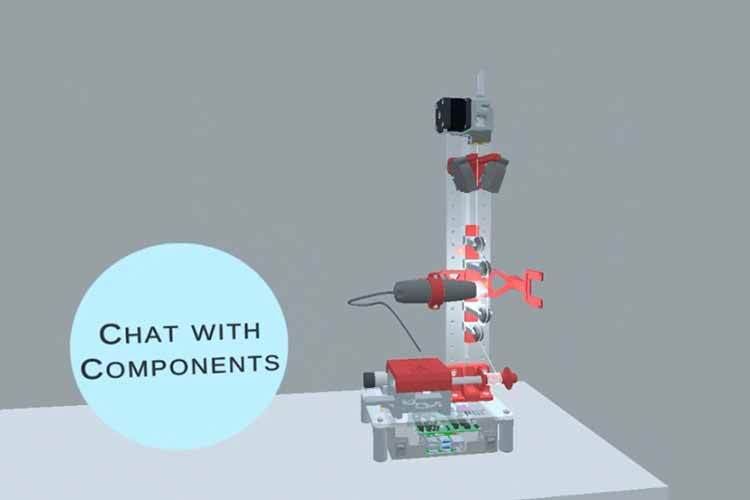

At the heart of the project is the digital version of FrED (Fiber Extrusion Device), an educational mechatronic tool originally developed at MIT. It was designed as a hands-on learning platform that bridges theory and practice in data analysis, control systems, and smart manufacturing. In the virtual lab, students can take FrED apart, redesign it, and test technical and commercial proposals.

“FrED is the lab’s centerpiece—a teaching extruder that explains itself. It shows you its components, how it works, how it’s programmed, and why specific parts were chosen,” Ponce adds.

Researchers chose this device because it reflects the advanced manufacturing work at MIT and Tec. However, the lab is fully customizable—it can be adapted to simulate the development of virtually any product. The skills students gain are widely transferable to other systems, equipment, and industrial processes.

Pitching a Project to AI Avatars

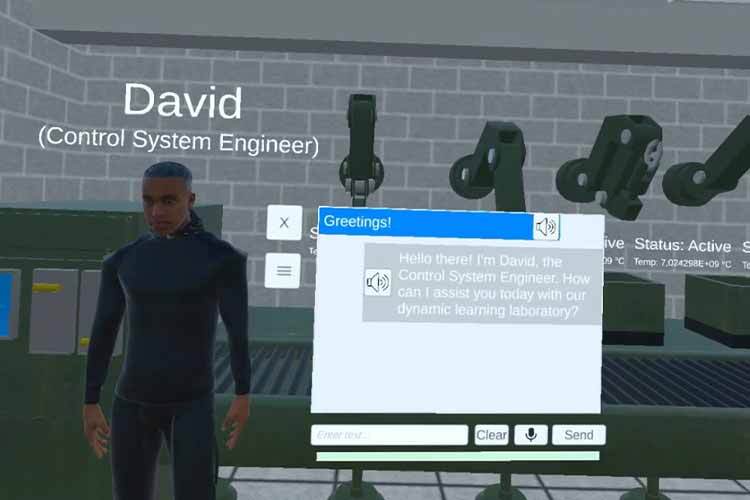

The virtual plant also features dedicated rooms where users can interact with expert avatars representing a range of professional profiles—from technical advisors and engineers to a virtual CEO.

That’s one of the key features that sets this lab apart from others, says Ponce: the use of large language models (LLMs) allows students to receive real-time feedback on their proposals in a way that feels natural, coherent, and specialized—almost like presenting to real professionals.

These avatars are trained using domain-specific knowledge in areas across the supply chain, such as control engineering, mechanics, digital systems, and business strategy. They simulate expert behavior and serve as mentors throughout the learning process, offering guidance and support, without spoon-feeding solutions, so students can build their answers and insights.

Interaction with these virtual experts can take place via text or voice, depending on the user’s device—whether a VR headset, tablet, or smartphone—and the lab’s settings.

“You start by figuring out how a device works, then consult with the experts in each area until you shape a technically sound proposal,” Ponce explains. “Then you pitch it to the CEO avatar, an expert in technical, commercial, and product-launch strategy. That’s when it feels like a ‘Shark Tank’ moment—you must make your case and convince them it’s viable.”

The avatars can also be customized to reflect different cultural and regional business styles—for instance, a CEO with an Asian, North American, or South American profile—allowing students to experience different negotiation approaches. The number of digital mentors and their specialties can be tailored to fit the course or simulation, ranging from legal and regulatory advisors to entrepreneurship, sustainability, and circular economy experts.

International Collaboration Between Tec and MIT

Ponce explains that the idea for the virtual lab emerged while he was doing a research stay in the advanced manufacturing group at MIT. The institute contributed ideas, validation, and technological development to bring the project to life, and it offered complete flexibility for Tec to adapt and customize the platform as needed.

Researchers from both institutions are involved in the scientific and technological development of the project, including Brian Anthony and Russel Bradley from MIT and the FrED team, as well as Joan Guerrero, Isabel Méndez, and Omar Mata from Tec’s Institute of Advanced Materials and Sustainable Manufacturing and the School of Engineering and Sciences.

“This kind of project only works through collaboration with academic peers from other universities. It speeds up the exchange of ideas and gives you different angles to tackle a problem,” says Ponce. The research is also supported by Adriana Vargas, who leads the cooperative alliance between the two institutions.

The virtual lab already has a working version, which was tested by a small group of students—with positive feedback—and is currently in the validation phase. The team fine-tunes elements like avatar interaction, personalization, and factory simulation. Their next step is to run a complete pilot in a classroom setting and compare learning outcomes between students who use the platform and those who don’t.

One of the main goals is for the platform to be accessible from any device, available at any time, and adaptable beyond engineering, for use in any field of knowledge, whether academic or professional.

The team also envisions expanding the platform into industrial environments through the concept of digital twins. That would allow companies to test and validate processes or products in a virtual factory replica before rolling them out in the real world.

Did you find this story interesting? Would you like to publish it? Contact our content editor to learn more at marianaleonm@tec.mx