Although electromobility is increasing in Mexico (in 2021 alone, the sale of more than 42,000 vehicles with electrified technology was reported), there are still challenges that don’t let the electric car market to increase.

One of them is batteries, because of their high costs and even failures in their production, problems that could be solved with technology, such as Artificial Intelligence.

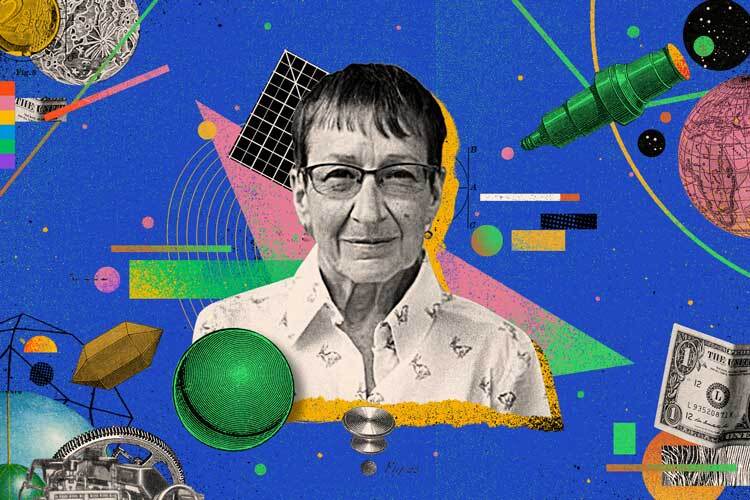

Brian MacCleery, an American researcher and author created a system that detects failures in the production of lithium batteries, which helps reduce waste and the cost of vehicles that use them.

In addition, it reduces the environmental impact since, the fewer defective batteries, the less waste.

Jorge Lozoya, a Tec researcher, explains that the research of the groups dedicated to electromobility will be fundamental in the development of electric vehicles, especially with the arrival in Mexico of companies such as Tesla and the promotion of centers such as the Institute of Advanced Materials and Sustainable Manufacturing.

“The electric vehicle and the internal combustion vehicle were created at the same time, but since there was a lot of oil, electromobility is 60 or 70 years behind, especially in the energy part. We need technological development to be leaders at the Latin American level”, says Lozoya.

Electromobility: technology to prevent battery wear and failure

In 2020, MacCleery collaborated on research to improve the engine system together with Arturo Molina and Pedro Ponce, professors at the School of Engineering and Sciences and researchers at the Institute of Advanced Materials and Sustainable Manufacturing at Tec de Monterrey.

The researchers developed system improvements to prevent motors from losing power while maintaining an ideal temperature, and in the case of electric vehicles, this can reduce battery wear and improve battery life.

In an interview with TecScience, MacCleery also explains how he uses Artificial Intelligence to detect problems in electric vehicle batteries.

“Batteries have a temperature, voltage, charge, and other factors. For our brain, it is sometimes difficult to solve these problems by thinking about several of them simultaneously. That is where I think Artificial Intelligence comes in, to help us solve these challenges,” he says.

His process consists, first, of dividing complex equations into parts, for example, that of conservation of energy, and using intuitive artificial intelligence, that is, tools similar to Chat GPT, to understand and solve these problems from the root.

MacCleery exemplifies this with the uranium nuclear fission equation −which deals with how energy is released in the form of heat and radiation− and ensures that it is possible to use algorithms to find better solutions more quickly since, for humans, it is a lengthy process and even impossible to solve or improve.

“We can ask Artificial Intelligence to write us programming code to help us simulate battery tests and detect problems,” says MacCleery.

This working model created by the researcher is responsible for testing faster and more efficiently to detect defects in battery cells and prevent them from causing fires and explosions.

These production failures do not represent a significant loss of money for established companies like General Motors and Tesla, but they do for emerging companies or startups.

Besides, lithium batteries cannot yet be fully recycled, so having batteries exploding or igniting, and thrown away, represents a negative impact on the environment.

Failures increase battery costs, driving up the ultimate price of electric vehicles.

Even though the specialist gives this use to AI, he assures that the technology is not the total solution to the problem, but rather a tool to help scientists, researchers, and engineers in their work to investigate and improve the manufacturing processes of products. electric vehicles.

Not only in battery failure detection but also in other aspects of electromobility, such as autonomous vehicle systems and their safety systems.

Research and technology take the next steps

According to the report Electric Mobility: Advances in Latin America and the Caribbean, in 2020, the automotive sector was responsible for 15% of total air polluting emissions.

Although some metropolitan areas of the country, such as Mexico City, offer electric transport alternatives, some have been seen to be inefficient and have even decreased, such as the trolley network in the Mexican capital, which from 2017 to 2023 presented a decrease of almost 25%.

Also, according to the Mexican Association of Automotive Industry (AMIA, in Spanish), in Mexico, there is a lack of incentives to promote hybrid and electric vehicles.

Although there are currently some discounts at toll booths and preferential charging station rates, AMIA itself points out in its report the need to follow in the footsteps of other regions.

Such as implementing the development of charging infrastructure for electric cars and approving the tax deduction in the purchase of electric and hybrid vehicles by 100%.

Not everything is bad. Some electromobility projects in Mexico have shown growth, such as including electric buses in the public transport system of cities such as Guadalajara, Monterrey, and Hermosillo.

Researchers such as MacCleery and universities such as Tec de Monterrey have also launched various initiatives to work on this type of project, serving as a link between industry, government, and researchers.

For example, in 2022, the Mercedes-Benz company signed an alliance with the School of Engineering and Sciences for the development of electric buses that can be commercialized.

Likewise, Tec researchers Javier Izquierdo, Ricardo Ramírez, Martín Bustamante, Sergio Navarro, and Roberto Ávila created a system called ADMAS that monitors drivers’ emotions in real-time, which can provide data for autonomous driving systems and decrease or avoid traffic accidents.

Likewise, José Huertas, an EIC researcher, works to promote electric vehicles in areas such as transportation within cities and also for last-mile distribution.

His research proposal indicates that using electric vehicles in these areas reduces CO2 emissions by 31% and total costs by 29%, compared to bus systems using diesel.