By Carlos Alberto Huerta Aguilar

Historically viewed as “useless” and often “problematic,” the byproducts of chemical reactions are gaining new significance. Advances in chemical engineering have given rise to the innovative field of “Green Chemistry.” This discipline prioritizes efficiency and waste minimization, shifting away from the 20th-century focus on sheer volume of production.

This new paradigm is driven by necessity but fueled by curiosity and entrepreneurship. As traditional resources decrease in their availability, extraction processes become complicated and it creates the necessity for new sources or substitute materials.

Can we capitalize on the fact that transformation processes—where substances or materials are chemically altered—inevitably generate residues? Is it feasible to benefit from the reality that no chemical reaction is 100% efficient, meaning not everything transformed results in a useful product and there are always byproducts? How can we turn these residues, often seen as waste, into valuable resources?

Even in the pharmaceutical industry where reactions are well controlled and yields could rise to 99% will form copious amounts of residues when production is scaled up to tons per day1,2. Rather than labeling these residues as “problematic,” how can we turn them into valuable resources?

Circularity and Green Chemistry

If we think about the availability of materials and precursors, we can see that most of them are already in the production chains and the global trade web even though they are sometimes scattered as byproducts, residues and ullage. Now, the objective is to spot, recover and reuse them before they are discarded as residues or lost as contaminants.

Quantifying the composition and volumes of waste is therefore a key objective in industries that can reveal new sources of materials. For example, in Mexico, sugarcane facilities can produce up to 50 tons of refined sugar per day during harvesting season3. However, the efficiency of this process is only around 10% which means that for every kilogram of sugar, there were more than 9 kg of residues produced4. These residues were either discarded as rubbish, used as pasture for livestock, or in some cases burned as fuel.

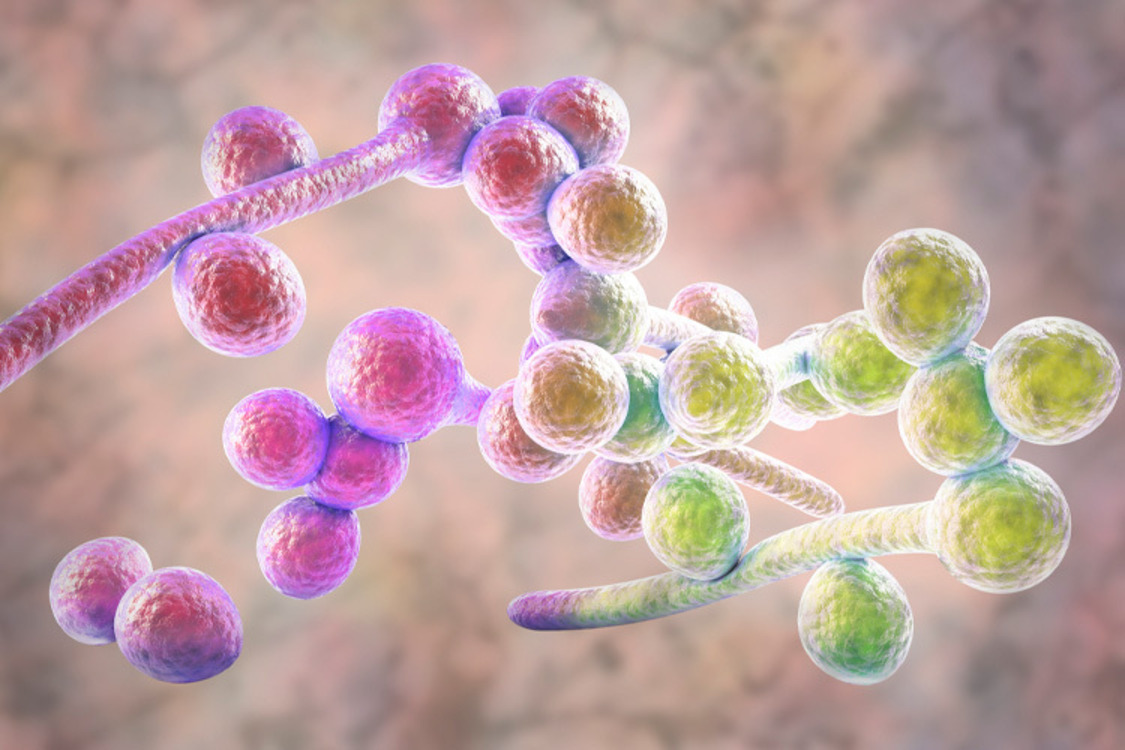

The new tendencies in chemistry and engineering seek to obtain new resources from this discarded material: extract and refine the cellulose from residual sugarcane to produce packaging; transform sugar contained in wood to produce fuel or plastics, recover raw materials during production to reintroduce them into production line; isolate bioactive and therapeutic agents present in fruit peels, etc.

In fact, the streams traditionally termed “residues” are now classified as alternative sources of materials and have passed from a problem to an economic opportunity as there is high economic value in materials just waiting to be extracted and exploited.

At Laboratorio de Energias Renovables (LER), Puebla, green Chemistry initiatives have been focusing on finding new uses for residues from agriculture, biodiesel production, and steel manufacturing; also, we are focused on extracting biomolecules with therapeutic applications such as coffee, cashew nuts and fruit residues.

These projects seek to create new chemical processes that could be highly efficient and readily applicable in the region, contributing to the economic development all over the productive chain starting from new economic revenue for farmers and finishing with new products locally gathered and produced.

Green Chemistry at Tec

At the most recent meeting of the American Chemical Society (ACS), the focal point revolved around “Food Chemistry,” emphasizing the use, exploitation, and scaling up of chemistry in the food industry. But also, there was a special emphasis on resilient agriculture, preserving lands and ecosystems, and new applications and uses for discarded materials during food manufacturing to reduce waste and reuse materials.

During this event, our research team presented different talks; the first one came from a collaboration with UNAM “High cationic charge influencing metal oxide for CO2 capture: Experimental and theoretical studies” centered on new materials to remediate carbon dioxide pollution and reuse it.

The other one was entitled: “Transformation of food and farming residues into commodity chemicals through visible light using iron oxide based catalysts” and is part of a project with the University of Ottawa. As can be inferred, there is a continuous interest and a growing trend in all industries and fields centered on the reuse of materials and energy known as circularity.

The discoveries are there, Chemistry and chemical engineering are mature fields and key actors in the fight against climate degradation and overexploitation of resources. It is now our turn to roll up our sleeves and work for it.

References

(1) Gascón, F.; Lozano, J.; Ponte, B.; de la Fuente, D. Measuring the Efficiency of Large Pharmaceutical Companies: An Industry Analysis. European Journal of Health Economics 2017, 18 (5), 587–608.

(2) You, T.; Chen, X.; Holder, M. E. Efficiency and Its Determinants in Pharmaceutical Industries: Ownership, R&D and Scale Economy. Appl Econ 2010, 42 (17), 2217–2241.

(3) Molina, J. P. Análisis de Capacidad de Planta y Punto de Equilibrio Financiero En Un Ingenio Azucarero. e-Agronegocios 2015, 1 (2). .

(4) Pandey, A.; Soccol, C. R.; Nigam, P.; Soccol, V. T. Biotechnological Potential of Agro-Industrial Residues. I: Sugarcane Bagasse. Bioresour Technol 2000, 74 (1), 69–80.

Author

Carlos Alberto Huerta Aguilar, Ph.D. is a researcher from the School of Engineering and Sciences in Campus Puebla. Born and raised in Mexico City he did BSc in Biopharma with MSc and PhD in environmental engineering from UNAM and later appointed as postdoctoral scientist at Stanford University. He is part Sistema Nacional de Investigadores and has published around 50 papers in reputed journals. His research focuses in green chemistry, water technology and sunlight catalysis with ongoing research projects with Canada, India and the USA.