Given the environmental issues represented by the use of industrial lubricants made with petroleum or mineral oil, Mexican researchers created an alternative using prickly pear -a family of cacti that is consumed as food in Mexico and Latin America- to create an organic lubricant that has the same performance.

Industrial lubricants are among the best-selling products globally, guaranteeing the proper functioning of different machinery. However, those that are created from petroleum or its derivatives are harmful to the environment and human health, which is why efforts are being made to produce biodegradable options.

“Currently, new alternatives (for lubricants) are being proposed, but only a few of them meet the necessary requirements for proper functioning,” says Leonardo Farfán, research professor at the Department of Mechanics and Advanced Materials at the School of Engineering and Sciences (EIC), Puebla Campus, at Tec de Monterrey, in an interview with TecScience.

These products are substances that extend the useful life of machinery, such as car engines, by reducing friction and temperature, and lubricating its moving parts.

The aerospace, automotive and construction industries are some of the ones that use them the most. Due to their importance, the industrial lubricant market has grown continuously with an estimated value of 63.9 billion dollars today and is predicted to grow to 74.3 billion by 2029.

“Normally they are made with mineral oil or oil derived from petroleum,” explains Farfán.

When used, they release waste from these oils in the form of vapor or tiny droplets that pollute the air, water and soils of ecosystems. It also has consequences on human health, such as skin diseases or irritation of different parts of the body of those who are in close contact with them.

In recent years, the negative impacts they have caused a need to replace existing ones with others made from renewable sources.

“For this reason, we sought to use the mucilage of this cactus to create a biodegradable option,” says the researcher.

A Water-Based Industrial Lubricant Made With Prickly Pair Mucilage

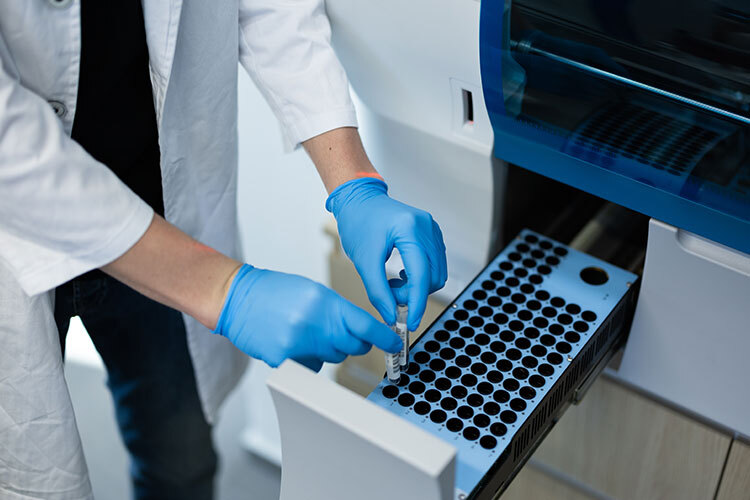

To respond to the increase in demand for non-harmful lubricants, Farfán led a team, in collaboration with José Pérez from the Higher School of Physics and Mathematics of the National Polytechnic Institute (IPN), that created a water-and-cactus-based lubricant.

Prickly pairs contain a substance called mucilage –that slimy stuff they release when cooked– which is viscous due to its hight content of lipids and fatty acids as well as soluble in water.

“We proposed the idea of evaluating it as a possible substitute for mineral oil and the emulsifier,” says the expert.

By generating mixtures of this substance with water, they created a fluid with properties very similar to those of petroleum-based oils used in commercial lubricants.

They tested different types and concentrations of this plant substance, and did performance tests until they found the perfect formula.

To their surprise, these mixtures not only increase the viscosity of the fluid –as do commonly used oils– but also increase its elasticity, “which does not normally happen with other additives,” says Farfán.

When comparing the performance of their biodegradable lubricant with that of a commercial one based on petroleum derivatives in different machinery, they found that it was equally functional and that the solution with the highest mucilage content was the one that resulted in the least wear, friction, and temperature.

“After it is used, it evaporates into the environment and disappears,” he says.

Manufacturing Costs Are the Challenge

The researcher says that the manufacturing technology they used to create the organic lubricant is complex and expensive, so the product is still in its initial stages to eventually reach the market.

Currently, they are working on a patent to register their product and advance to the next steps.

Something positive is that through different studies they were able to verify that their product is competitive in terms of performance, which represented a great challenge for them.

“Products made with (petroleum) derivatives have been adapted to present the highest performance,” contrasts the expert.

In addition to proving that their product is just as functional, the fact that it is obtained from a product that is abundant locally, such as the prickly pear, contributes to making it a sustainable product.

“As Mexicans we are producers of nopal, so using it to create organic lubricants can have a positive impact on our society,” says Farfán.

Were you interested in this story? Do you want to publish it? Contact our content editor to learn more marianaleonm@tec.mx