In the 1967 movie The Graduate, a businessman corners a young man fresh out of college to tell him: “There’s a great future in plastics.”

The scene depicts a time when plastic was starting to become a big business in the United States, but no-one could have imagined that this material would even come to pollute our bloodstream or breast milk 50 years later through microplastics.

We are facing a plastic crisis and science is looking for solutions. Among the lines of research are gaining more knowledge of microorganisms that degrade polymers and developing bioplastics that are reintegrated into the environment.

The solution can be found in nature, according to the paper Environmental impact and mitigation of micro(nano)plastics pollution using green catalytic tools and green analytical methods, which analyzes mitigation strategies based on the use of enzymes to break down polymers.

Published by María Fernanda Cárdenas Alcaide, a Nanotechnology Engineering student at the School of Engineering and Science at Tec, and directed by professor Hafiz Iqbal, the paper explains that we need to find “a practical, feasible, and environmentally friendly strategy to tackle the current crisis of plastic pollution.”

“Different microorganisms have developed capacities in plastic utilization, turning it into food, into energy. More than 90 microorganisms have been discovered, including fungi and bacteria, which have demonstrated abilities to degrade plastic wastes,” says the young researcher.

According to Cárdenas Alcaide, if marine pollution continues at the current rate, there will be more plastic than fish in the oceans by 2050.

Plastic crisis alternatives

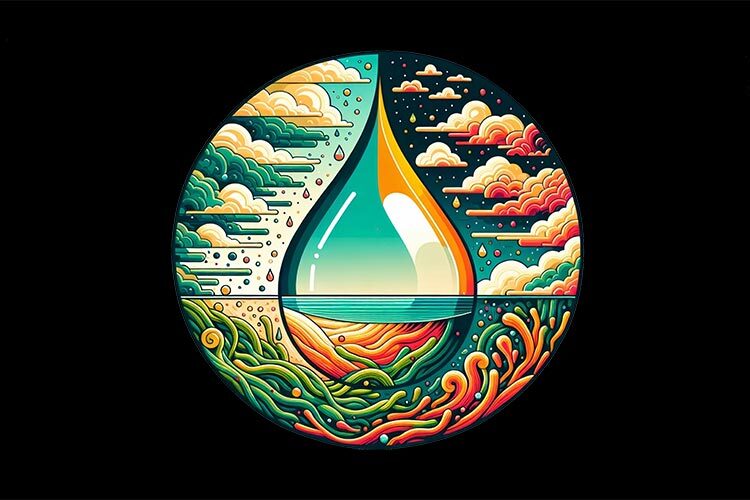

The Institute of Advanced Materials for Sustainable Manufacturing aims to generate alternatives to reduce the use of plastics derived from oil. The leader of the Accelerated Materials Development Unit, Dora Iliana Medina, explains that it’s about innovating on the development of bio-based polymers (also colloquially known as bioplastics).

“Renewable sources produce plastics that can undergo recycling and biodegradation. They’re compostable. Currently, all the waste material from the agrifood industry can be used to make bioplastics,” explains Medina.

For instance, when drinking straw companies were forced to stop using traditional plastic, they started using bagasse from sugar cane or corn to produce new straws that can be reincorporated into nature after use. Medina says that the steps for creating these materials are quite simple.

Once the bio-based material has been chosen, it is chemically treated, and the compound of interest is isolated.

“Industrialization is the big challenge, as the market favors plastics because the prices are lower than for natural products. It’s going to be a bit more expensive because it’s an innovation,” she warns.

Plastic: A misused material

Cecilia Treviño Quintanilla, also a researcher at the Institute of Advanced Materials for Sustainable Manufacturing, says that plastic’s mechanical properties make it the perfect material. What’s more, the fact that it’s easy to process makes it very economical.

She says that the problem lies in humanity using a material that lasts for millions of years in a disposable manner.

“When plastics are exposed to solar rays, their chains break down and they become smaller. Microplastics have even been found in human urine,” says the polymer specialist.

Treviño Quintanilla is investigating how to become part of the solution to the plastic crisis. She’s currently working on a project to degrade rubber, a material we can’t yet recycle.

“Polymers are chains, so what we’re doing is using a chemical process to break them apart. Once all the bonds have been broken, we can make another rubber out of them,” she explains.

Her research, in collaboration with the Southwest Research Institute (SwRI), aims to make it possible to recycle even vulcanized tires.