A team of researchers from Tecnológico de Monterrey Campus Querétaro has developed a process that could revolutionize one of the world’s most persistent waste problems. Their target: butadiene rubber, a synthetic material as ubiquitous as it is problematic globally.

Cecilia Treviño-Quintanilla, a chemical researcher at the Institute of Advanced Materials for Sustainable Manufacturing who was part of the team, explains how this material is the most common rubber used in industry: “In hoses, in seals, shoe soles, latex gloves, in cow milking teats.” The problem isn’t its use but its disposal. “It takes millions of years to degrade and isn’t used for absolutely anything,” says Treviño-Quintanilla.

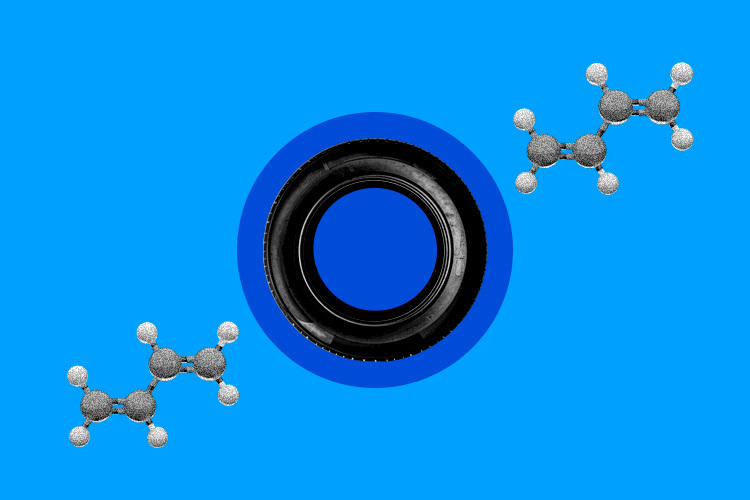

The problem lies in the molecular structure of butadiene rubber itself. Unlike many materials that can be melted and reformed, this synthetic elastomer has cross-linked molecules that resist recycling. “When you apply heat, the molecules don’t relax,” explains Treviño-Quintanilla. “There’s simply no way to break them down using traditional methods.”

The Environmental Challenge of Rubber

In a recent study published in Polymer Degradation and Stability, researchers demonstrated that degradation through the metathesis process of butadiene rubber produces polyols and polyesters with yields of up to 97%. The polyols and polyesters obtained are high-value raw materials, laying the foundation for future industrial application in tire recycling and other waste.

The scale of this waste crisis became evident during the COVID-19 pandemic: While automotive production decreased, leading to a less demand for rubber components, the increase in medical waste compensated for this reduction. “Everyone was wearing gloves,” said Treviño-Quintanilla. “Doctors had to use a pair of gloves for each patient they saw. The amount of waste generated during the pandemic increased exponentially.”

Perhaps nowhere is this waste problem more visible than in the tire industry, where butadiene rubber serves as the main component. Millions of discarded tires accumulate in landfills worldwide, representing a significant environmental challenge. Current recycling methods are limited and insufficient: grinding tires for use in outdoor courts or road materials can only absorb a small fraction of the generated waste.

“How many courts can exist? How many running tracks can exist to compensate for the amount of tires thrown in the trash?” questions Treviño-Quintanilla.

Breaking Down Butadiene Rubber at the Molecular Level

Using a chemical process called metathesis, they have found a way to break down butadiene rubber at the molecular level, transforming solid waste into valuable liquid raw materials. The process focuses on the double bonds within polymer chains: the weakest points in the molecular structure.

The elegance of this approach lies not only in its effectiveness (the process achieves approximately 90% efficiency), but in its circular economy potential.

According to their results, the process is effective and could potentially increase the circular economy of this material. The liquid products obtained through metathesis are polyols, valuable raw materials typically derived from petroleum and used extensively in coatings, paints, automotive components, and aerospace applications.

“We’re obtaining raw materials that have commercial value from what was essentially trash,” said Treviño-Quintanilla.

Scaling Up the Innovation

The research team has successfully demonstrated the process in the laboratory and now faces the complex challenge of industrial scaling. This involves everything from reactor design and catalyst recovery to separation processes and cost analysis.

The implications extend far beyond waste management. Industries ranging from automotive to aerospace could benefit from this sustainable source of raw materials. Instead of relying solely on petroleum-derived compounds, manufacturers could incorporate recycled materials without compromising quality or performance.

With support from Tec, including assistance with patent applications and funding searches, the team is actively seeking industrial partners to help scale the process. The typical scaling timeline is 18 months, but the complexity of transitioning from laboratory to industrial production means the process has just begun.

Removing the Stigma from Polymers and Plastics

For Treviño-Quintanilla, this research represents more than just scientific innovation: it’s about changing perceptions. “I’m always looking to remove the stigma from polymers and plastics,” she says. “So that it’s seen that they have a dual use, that they’re not just something disposable, and trying to reduce the environmental impact of plastics and find another use for them.”

While the world struggles with the growing problem of plastic waste, solutions like metathesis offer hope that our trash could become something useful while expanding the circular economy.

Did you find this story interesting? Would you like to publish it? Contact our content editor to learn more at marianaleonm@tec.mx