After World War II, a second industrial revolution in manufacturing began replacing traditional materials with polymeric materials, namely, plastics. The digital revolution triggered a surge in computer and cell phone usage, leading to a sharp increase in the disposal of these materials.

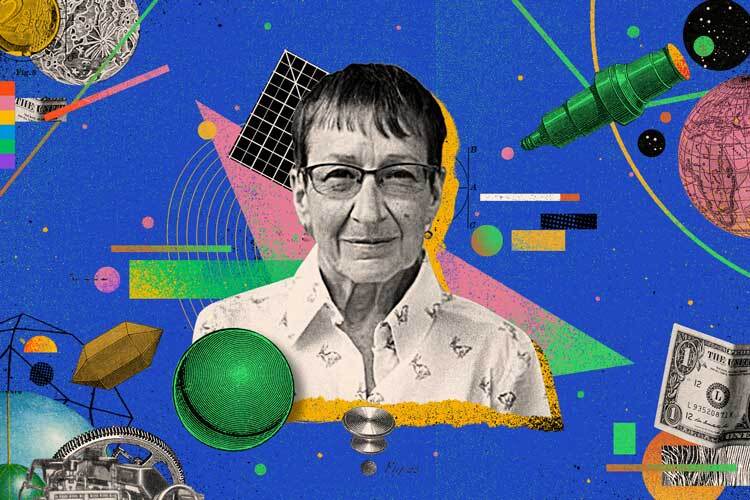

During a Science Fair videoconference, researcher Cecilia Treviño Quintanilla cited these references to illustrate the challenge confronting the manufacturing industry in developing environmentally friendly materials. Currently, 50% of global waste consists of plastics and rubbers, contributing significantly to the plastic crisis.

“With technological development, there is always a price to pay. Yes, we have developed, but globally we also started producing more plastic waste,” explains the researcher from the Institute of Advanced Materials for Sustainable Manufacturing (IAMSM) at Tec de Monterrey.

Polymeric materials are used in all industries. Although the packaging sector is identified as their main user, they are also massively used in textile manufacturing—with polyesters and polyamides, the latter better known as nylon—in construction for drainage, plumbing, thermal and electrical insulation, as well as in the medical sector with various devices ranging from syringes to catheters.

Industries such as aerospace, automotive, and telecommunications are also major consumers of plastic components.

Challenge: New Materials

“Why do we keep using plastics if there are so many problems associated with these materials? They are very easy to produce, but above all, they are very cheap,” explains Treviño.

She adds that of all the plastic discarded worldwide, only 9% is recycled, 80% ends up in landfills, and approximately 11% is discarded into the environment. It is estimated that 8 million tons of polymeric materials are dumped into the ocean annually.

The impact of industrial consumption of polymeric materials demands that humanity produce and use materials that are sustainable. This is the main objective of the Institute of Advanced Materials for Sustainable Manufacturing (IAMSM), which, since its inauguration in 2022, has been promoting research on sustainable production processes through the creation of advanced materials.

In this context, the IAMSM proposes the model called “5S Materials”: Social, (solving social problems), Sustainable (net zero impact), Sensing (being context aware – sense conditions), Smart (reacting to stimulus to improve performance) and Safe (no hazzard to society or users).

The initials of these characteristics are attributes and properties present in these new man-made materials that meet a standard to reduce the environmental impact to zero, in addition to providing additional usage benefits.

5S Materials aim to meet the needs of various industries while not creating ecological or social problems even after their useful life has ended.

The Materials of the Future

Arturo Molina Gutiérrez, director of the IAMSM, explains that they developed the concept to create the materials of the future. “Everything around us is made of materials that have been transformed into products through manufacturing processes. We must ensure these materials have zero impact on the carbon footprint, generate no waste, and that the manufacturing processes for these materials are efficient, waste-free, use little to no water, utilize clean energy, and are part of the circular economy,” says Molina.

He warns that currently, the industry represents 17% of the GDP in Mexico, employs 9 million people, and contributes to 89% of the country’s exports. However, it also consumes 51% of the electricity, generates 12% of greenhouse gas emissions, and uses more than 70% of the water. “Our challenge is to turn it into sustainable manufacturing,” he states.

Tec de Monterrey has 70 researchers in interdisciplinary teams developing 5S Materials.

In an interview with TecScience, Reyna Berenice González González recounts how she began developing a material that met the five characteristics of these future materials without realizing it.

As a researcher at IAMSM, she develops organic coatings to protect fruits, intending to extend the product’s shelf life while providing information about the food’s quality through this smart film.

“We are generating advanced materials synthesized from waste. We have used tires, fruit peels, and juices. It is interesting that we are giving new use to something considered waste and not just as a second option but as added value, as we are creating materials with interesting properties, such as sensing or detecting changes in the environment,” explains González.

In summary, she adds, these are materials “produced under ethical standards, environmentally friendly, safe, and capable of integrating technology to solve current problems.”

5S Materials and Their Values

- Social

Socially responsible materials are developed to address community issues. In the case of organic plastics, they solve consumer needs for packaging and transporting food. This also means that they are developed according to social and industrial demands, such as the demand for lighter materials in transportation, which helps reduce energy consumption and emissions.

- Sustainable

A sustainable material has a neutral carbon footprint and zero waste. When materials are developed from the outset with organic principles, they can return to the environment without causing harm. At IAMSM, 100% reusable, recyclable, or compostable bioplastics are being developed, allowing their lifecycle to be planned.

- Sensing

The “sensitivity” characteristic of a material is the most futuristic. In Spanish, “sensible” implies that these materials can sense their environment and, therefore, can gather data from it and respond accordingly. For example, these materials can detect temperature, viruses, or chemicals and react to those variables. In the case of organic films for fruits, they have fluorescence capabilities, and research is ongoing to utilize this quality to activate in response to changes in pH or other variables, providing information to the consumer about the food’s condition.

- Smart

A smart material goes hand in hand with its ability to be sensitive to its environment and respond intelligently to enhance its performance. For example, materials that can halt the deterioration process of fruits when they detect environmental changes are considered smart. At IAMSM, nanofluids (fluids with nanoparticles) are being developed to optimize energy consumption by improving the performance of air conditioning systems. Additionally, materials that can absorb and release large amounts of heat are being developed to reduce operating temperatures and optimize energy consumption in buildings.

- Safe

The safety of a material means it is reliable and does not harm the environment or people. Safety can be exemplified in the agricultural industry, where to ensure food safety and reduce environmental impact, compostable bioplastics and biopesticides, among other materials, are being developed, which do not come from petroleum.

“Substitute,” the Sixth S

One of the most promising developments for 5S Materials is the creation of biodegradable and smart bioplastics that meet the five characteristics of the standard proposed by Tec to develop cutting-edge materials. Treviño Quintanilla aims to molecularly separate rubbers and plastics to recover their original ingredients and reuse them. They are also exploring how to recover carbon fibers from aerospace and automotive industry waste to develop smart textiles that can measure and react to changes in temperature and pH.

In other words, the new materials also address the social and environmental problem of waste management by converting waste into new materials that are environmentally friendly and have new qualities. Another line of research Treviño is involved in is creating single-use bioplastics from polylactic acid derived from milk. When mixed with coffee grounds and avocado pits, it creates a film that disintegrates under normal conditions after disposal.

As the director of IAMSM, Arturo Molina believes there is the capacity to discover, characterize, and create these new industrial inputs. “We are focused on addressing the challenges of the manufacturing industry in Mexico to achieve sustainable manufacturing using the materials of the future,” he says.

Were you interested in this story? Do you want to publish it? Contact our content editor to learn more about marianaleonm@tec.mx