In 2020, carbon dioxide (CO2) in the atmosphere reached 413 parts per million (ppm). This is especially serious because CO2 has a massive capacity for global warming.

So, the more CO2 there is in the atmosphere, the greater the planet’s average temperature increases.

Although global warming is caused by the emission of different polluting gases such as nitrous oxide or methane into the atmosphere, carbon dioxide has risen excessively due to the burning of fossil fuels such as gasoline, natural gas, or coal, which are used in industry and transport.

“Reality is that CO2 beats practically all the other greenhouse gases in quantity. That’s why people around the world are more aware of it,” explains researcher Alejandro Montesinos Castellanos, from the Institute of Advanced Materials for Sustainable Manufacturing at Tecnológico de Monterrey.

How to reduce co2 emissions CO2

Under pressure from environmentalist movements and global agreements on the climate emergency, large companies have set out decarbonization strategies that propose reducing fossil fuels burning in their production processes, thereby reducing their carbon dioxide (CO2) emissions to the minimum.

Amazon, Apple, Nestlé, Sony, and Walmart are some of the companies that have published their strategies for reducing, and even eliminating, their emissions of this gas.

However, studies like the Corporate Climate Responsibility Monitor 2022, which is conducted by the NewClimate Institute in collaboration with Carbon Market Watch to evaluate the climate strategies of 25 global companies, shows that most of these actions are, in reality, “ambiguous pledges” with “limited reduction commitments.”

Strategies for reducing emissions are applied to the energy sector and the creation of new technologies and renewable energy yet many new technologies are expensive or in preliminary phases, as the International Energy Agency (IEA) reported back in 2021.

Furthermore, it is not viable for many companies to transform their entire production system in the short term.

Scaling up

One of the technologies being promoted most vigorously to comply with decarbonization agreements is capturing CO2 quickly and efficiently.

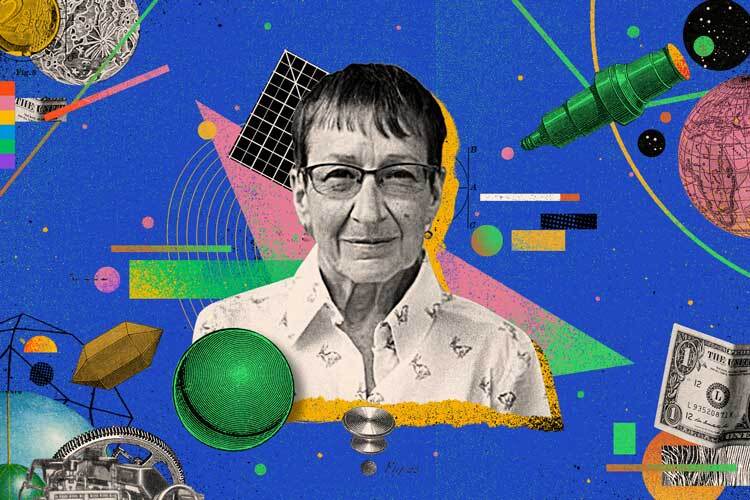

An example of this is Alejandro Montesinos research work. In recent years, he has specialized in developing materials that enable carbon dioxide to be captured, used, and mitigated.

The technologies used to capture CO2 have been industrially viable and functional for decades. Basically, they use liquids or solids through which CO2 is passed to trap its molecules.

“Technological challenge of CO2 capturing is mostly solved yet what to do with it once it’s been captured”, Montesinos says.

Generally speaking, there are two routes. One way is to reuse it and transform it into something useful like methanol, urea, methane, or even purify it for use in certain foods.

“For example, some steel companies capture CO2, purify it to 96%, and sell it to other companies specialized in gas purification. Those companies purify it from 96% to 99.999% to turn it into a food-grade product, and that’s the CO2 which is used to make sodas fizz,” the researcher explains.

Transforming CO2

The reactions that transform CO2 into something useful require catalyzing materials to accelerate them.

That is part of the work cut out for Montesinos and his team, who are currently developing a project that focuses on generating materials to accelerate reactions and enable CO2 to be transformed into methanol.

The other route available is CO2 capturing and burying it. One of the challenges of this method is finding mines with specific geological components to store CO2.

Montesinos’ work consists of developing environmentally friendly solid materials that enable the greatest amount of CO2 to be captured so that it can be buried afterward.

The CO2 is passed through solids –generally, stones containing calcium and/or magnesium– to turn it into a carbonate that can be stored in mines for centuries.

Reusing CO2 in manufacturing processes

Alejandro Montesinos believes that this area of research will become more important to many industries, which is why this is one of the Institute of Advanced Materials’ strategic projects.

“Companies that want to sell abroad must demonstrate that they’re doing something to lower their CO2 emissions. Companies using fossil fuels are morally and ethically committed to reducing those emissions”, he says.

Currently, Montesino’s team is evaluating the CO2 capture technologies available on the market as well as developing devices and prototypes for specific applications.

“Our goal is to facilitate the process and scale up the national and international manufacturing industry migration to zero-carbon economies,” he concludes.