By Danay Carillo Nieves y Sara Cristina Saldarriaga Hernández

While savoring a beer, we rarely stop to think about what happens to its ingredients after they’ve served their purpose. Yet, in Jalisco, the end life of these ingredients sparked the beginning of an innovative initiative aimed at promoting a Circular Bioeconomy throughout the state.

Our research has successfully transformed brewer’s spent grain into a range of valuable new products. Among these is a nutritional supplement that can be incorporated into bread and pizza dough to enhance the nutritional value of these foods.

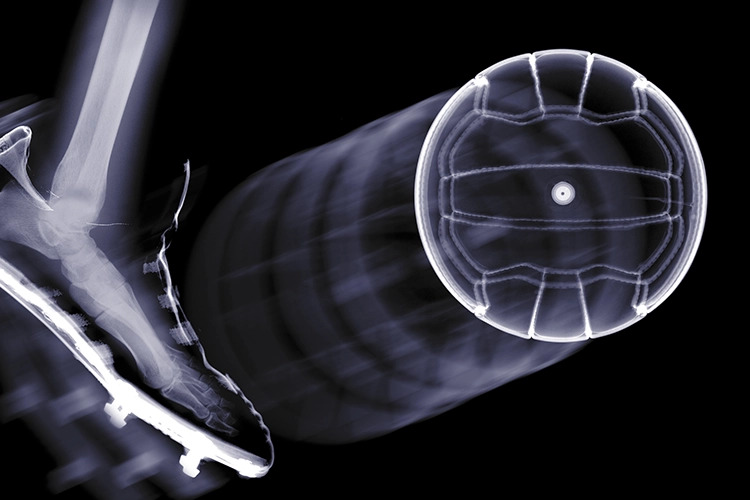

Brewer’s spent grain is a fibrous byproduct produced during the milling and mashing of barley grains (and other cereals) in beer production. This material is left over after fermentable sugars have been extracted from the mashed grains, yielding a sugar-rich liquid called “wort.” This wort is then boiled, fermented, and ultimately transformed into beer.

The spent grain is removed and often discarded. However, this byproduct constitutes 85% of the waste in beer production, presenting a considerable challenge in terms of logistics and waste management for the industry.

Nevertheless, the rich composition of proteins, carbohydrates, and fiber in brewer’s spent grain captured our interest as researchers. This prompted us to partner with Grupo Cielito Lindo, an independent craft brewery in the region, to repurpose this byproduct into a valuable resource.

Brewing Byproducts

The Carrillo Biorefinery Lab team has successfully orchestrated an inter-institutional collaboration involving Tecnológico de Monterrey and esteemed partners such as the Research and Assistance Center in Technology and Design of the State of Jalisco (CIATEJ) and the Lawrence Berkeley National Laboratory (LBNL) of the U.S. Department of Energy.

Together, they implement advanced and environmentally friendly technologies to transform brewer’s spent grain into ethanol (alcohol), the main product intended for its application as a bioenergy source. Other products derived from the process includeui plant growth promoters and molecules with potential nutritional value (Saldarriaga-Hernández et al. 2020).

This joint project aims not only to reduce greenhouse gas emissions from fossil fuels and minimize the environmental impact of petrochemical fertilizers but also —in collaboration with the local agency for Comprehensive Family Development (DIF in Spanish)— to provide nutritional alternatives that improve the quality of food in community dining facilities in Jalisco.

The objective is to create a versatile circular economy model that can be adopted by various breweries. This model would not only enable breweries to add value to their waste through direct transformation processes or on-site management but also encourage the establishment of new enterprises that utilize brewer’s spent grain as a valuable resource and a promising raw material.

Spent Grain Pizza

The transformation of brewers’ spent grain into valuable products is a clear example of how innovation and the circular economy integrate with the industry. This project not only aims to minimize waste and its environmental impact but also facilitates access to functional foods and promotes community well-being.

The combination of pretreatment with Deep Eutectic Solvents (DES) and commercial enzymes achieved the best conversion of fermentable sugars to ethanol, reaching yields of up to 20g/L of alcohol per gram of brewer’s spent grain.

Given the promising composition of the spent grain revealed in our prior characterizations, we anticipate a potential increase in ethanol yield. In the next stage, environmentally sustainable solvents similar to DES will be used to perfect the fermentation process.

With the remaining solid fraction, previously characterized, snack-type rolls and pizza bases were formulated in test prototypes. These products underwent sensory evaluations, demonstrating notable acceptance when the proportion of spent grain in the mixture with wheat flour reaches 20%.

With this addition of spent grain to wheat flour, fiber content has been increased, opening new research avenues on the prebiotic advantages of these foods and their potential health benefits.

Waste Transformation

The process is divided into four key phases:

Phase 1: Characterization of spent grain. It is necessary to understand the fermentation potential of brewer’s spent grain, that is, how much sugar it comprises and how much the spent grain needs to be degraded to achieve its extraction.

The spent grain is lignocellulosic, meaning it is composed of three main intertwined layers, with lignin acting as a protective barrier and forming the outer layer (Kumar and Chandra 2020).

The hemicellulose (a component that helps plants maintain their structure and provides fiber in the diet) also contains simple sugars. It is located in the middle layer, forming tendrils around the cellulose. Being rich in glucose, hemicellulose constitutes our main recovery target (Toor et al. 2020). The goal is to access the cellulose and hemicellulose to release the sugars necessary for fermentation, a process in which ethanol is produced.

Phase 2: Pretreatment and sugar release. In this stage, Deep Eutectic Solvents (DES), an innovative and environmentally friendly technology, break down the spent grain into main components, separate the lignin (a kind of plant cell glue), and improve access to fermentable sugars.

Together with the Lawrence Berkeley National Laboratory, the formulations of the Deep Eutectic Solvents are optimized to facilitate the separation of lignin from hemicellulose and cellulose. Additionally, biological treatments are applied to release the sugars needed for the next phase (fermentation), using both native Mexican fungi and commercial enzymes. These are capable of breaking down the hemicellulose and cellulose.

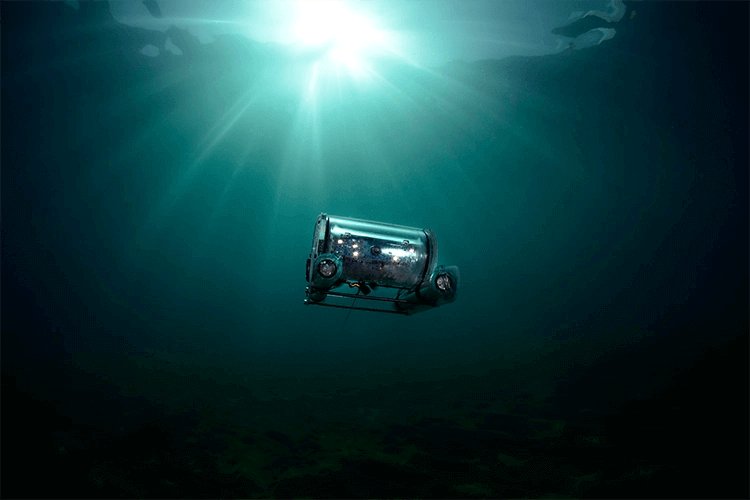

Phase 3: Fermentation. With the released sugars, fermentation proceeds using isolated and adapted yeasts. These yeasts convert glucose into alcohol under controlled conditions at CIATEJ facilities, which have specialized infrastructure for alcoholic fermentation at a pilot scale.

The produced alcohol is distilled, separating it from other compounds with potential use as plant growth promoters. The remaining solid fraction of spent grain and the biomass generated during yeast growth are filtered for application in food prototypes and exploring its use in the nutritional enrichment of baking flours. Thus, these fermentative transformation processes of brewer’s spent grain do not generate waste; all streams are used for various purposes.

Phase 4: Technical-Economic Analysis. Finally, to determine the project’s viability, a technical and financial analysis is carried out, also considering environmental aspects. This step ensures that the transformation process is well-founded and maximizes the possibility of success in the technology transfer of the project.

References

- Carrillo-Nieves, Danay, Magdalena J. Rostro Alanís, Reynaldo de la Cruz Quiroz, Héctor A. Ruiz, Hafiz M.N. Iqbal, and Roberto Parra-Saldívar. 2019. “Current Status and Future Trends of Bioethanol Production from Agro-Industrial Wastes in Mexico.” Renewable and Sustainable Energy Reviews 102 (November 2018): 63–74.

- Carrillo-Nieves, Danay, Héctor A Ruiz, Cristóbal N Aguilar, Anna Ilyina, Roberto Parra-Saldivar, J Antonio Torres, and José L Martínez. 2017. “Process Alternatives for Bioethanol Production from Mango Stem Bark Residues.” Bioresource Technology 239: 430–36.

- Carrillo-Nieves, Danay, Sara Saldarriaga-Hernandez, Guadalupe Gutiérrez-Soto, Magdalena Rostro-Alanis, Carlos Hernández-Luna, Hafiz M.N. Iqbal, and Roberto Parra-Saldivar. 2020. “Biotransformation of Agro-Industrial Waste to Produce Lignocellulolytic Enzymes and Bioethanol with a Zero Waste.” Biomass Conversion and Biorefinery.

- Kumar, Adarsh, and Ram Chandra. 2020. “Ligninolytic Enzymes and Its Mechanisms for Degradation of Lignocellulosic Waste in Environment.” Heliyon 6 (2): e03170.

- Saldarriaga-Hernández, Sara, Carolina Velasco-Ayala, Paulina Leal-Isla Flores, Magdalena de Jesús Rostro-Alanis, Roberto Parra-Saldivar, Hafiz M.N. Iqbal, and Danay Carrillo-Nieves. 2020. “Biotransformation of Lignocellulosic Biomass into Industrially Relevant Products with the Aid of Fungi-Derived Lignocellulolytic Enzymes.” International Journal of Biological Macromolecules 161: 1099–1116.

- Toor, Manju, Smita S. Kumar, Sandeep K. Malyan, Narsi R. Bishnoi, Thangavel Mathimani, Karthik Rajendran, and Arivalagan Pugazhendhi. 2020. “An Overview on Bioethanol Production from Lignocellulosic Feedstocks.” Chemosphere 242: 125080

.

NOTE: In 2022, this research proposal garnered attention and funding through various national and international calls, notably securing a grant from Tecnológico de Monterrey’s Research Funding Program Based on Challenges 2022 (grant number E091 – EIC-GI01 – C-T11 – D; 2022). A subsequent proposal, aimed at integrating a circular economy within breweries, was submitted to the Fund for Scientific Development of Jalisco (FODECIJAL) to address social challenges (FODECIJAL 2022, grant number 10261; 2022), facilitated by the Jalisco State Council of Science and Technology (COECYTJAL), Mexico. These grants have been instrumental in advancing the project. Following the successful implementation with Grupo Cielito Lindo, the objective is to scale this model across the national brewing industry to enhance sustainability and economic viability. The collaboration across sectors, including academia, industry, and government, fosters an ecosystem that encourages feedback and shapes relevant legislation. This project exemplifies the powerful synergy between academia (Tecnológico de Monterrey, CIATEJ, UC Berkeley), industry (Grupo Cielito Lindo), and government (COECYTJAL and DIF) in driving successful outcomes.

Authors

Danay Carrillo Nieves: Research professor at Tecnológico de Monterrey, affiliated with the Climate & Sustainability research core and head of the Carrillo Biorefinery Lab.

Sara Cristina Saldarriaga Hernández: PhD candidate in Biotechnology, responsible for project development. She is preparing for a research stint at Lawrence Berkeley National Laboratory (LBNL) focused on enhancing sugar recovery from spent grain.