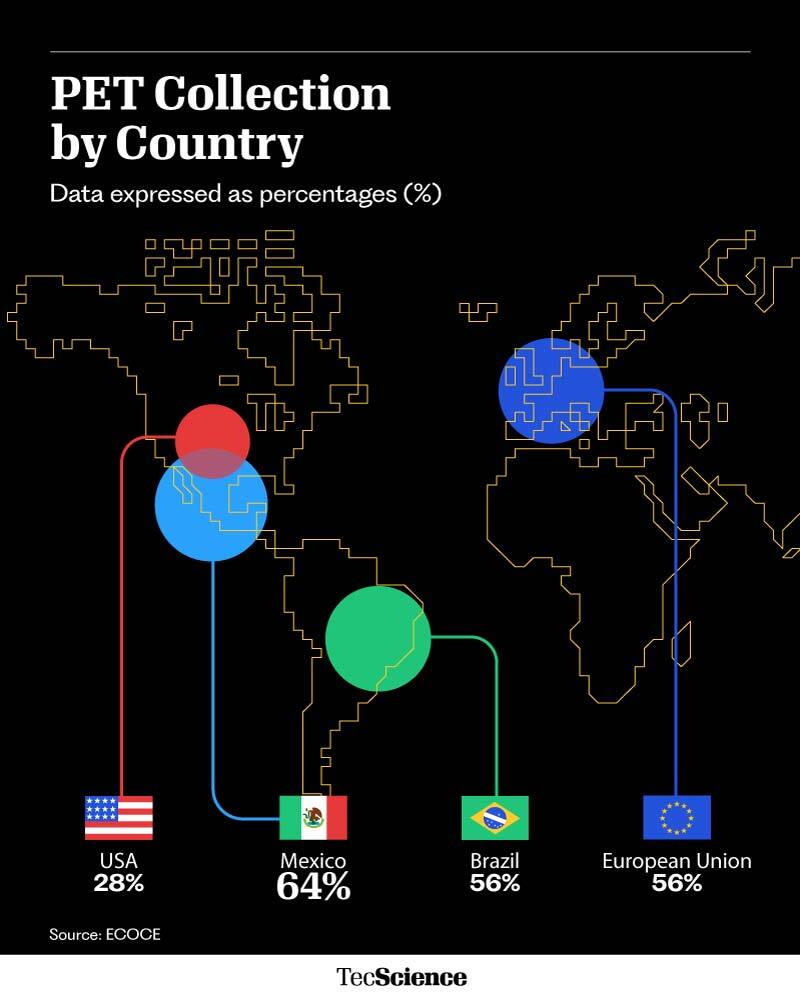

In 2023, Mexico used approximately 860,000 tons of PET (polyethylene terephthalate) packaging. About 63% of this material was recycled and repurposed through circular economy strategies. However, during recycling, this thermoplastic polymer can lose its original properties, making it harder to reuse, for example, in carbonated beverage bottles.

Gabriel Luna, Distinguished Professor of Smart Biomaterials at the Institute of Advanced Materials for Sustainable Manufacturing and the School of Engineering and Sciences at Tec de Monterrey, explains that PET’s properties degrade due to factors like sun exposure, temperature changes, and UV rays, which make the plastic brittle, cloudy, and mechanically weaker. Additionally, thermal recycling can further exacerbate its condition.

Faced with this challenge, Luna and a team of researchers are working on a project focused on recycling PET into high-value fibers and filaments that can be used in various applications, such as manufacturing textiles with antimicrobial properties.

Luna emphasizes that the project’s comprehensive strategy combines a scientific approach with recycling and circularity. “Our proposal is unique because it merges common technologies with smart formulations that allow us to recover and enhance recycled PET.”

Nanotechnology and Additives for Circular PET

Through circular economy principles, materials like PET can be kept in use for as long as possible, minimizing waste that harms the environment and reducing the need for virgin raw materials in product manufacturing.

While recycling remains the best option, it often requires restoring some of the material’s properties through the use of additive combinations.

The research team developed a formulation strategy—currently in the patent process—that uses metal oxide nanoparticles as additives. These particles must have specific sizes, shapes, and structures to ensure better chemical and physical compatibility with the polymer.

“It’s not just about adding materials; with the right formulation, we can combine them to produce a synergistic effect that helps restore or even enhance the properties that had been lost,” says Luna.

These additives serve a dual purpose: they restore physical qualities like strength, rigidity, shine, and durability to PET while also giving it antibacterial and antimicrobial properties. What sets this approach apart is both the underlying technology and its lower cost compared to other options on the market.

Building on this formulation, the researchers focused on producing fibers and filaments that could be used to manufacture high-quality textiles, wound-care materials such as patches and bandages, and even products with potential for 3D printing.

National and International Collaboration

Juan Carlos Tapia, an entrepreneur and scientist with nearly 30 years of experience in the textile industry and plastic waste recycling technologies, is one of Luna’s key collaborators on this project. He provides access to a facility equipped with extrusion and injection molding machines used to produce the threads.

The pilot phase of the project is taking place in Aguascalientes, where the researchers receive ground PET from recycling companies. They carry out a deep cleaning of the plastic and adjust its size to make it suitable as raw material. Then, they mix it with the additives and melt it down, followed by extrusion and injection processes to produce functional textile filaments.

According to Luna, the project could achieve circularity rates of 80 to 90% for this material. Additionally, at a pilot scale, up to 100 tons of PET could be recycled to evaluate the economic feasibility of the process, which could be scaled up if demand increases.

“Circularity means taking the material, processing it, using it, and trying to return it to the beginning in order to keep the cycle running for several loops,” he explains.

Luna also highlights an international collaboration with researchers at the University of Texas at Austin, to whom they send material samples for reformulation aimed at textile and other industrial applications.

Focus on Microplastics and Non-Recycled PET

While the project primarily focuses on circular PET, it also addresses microplastics generated from PET that is either not recycled or excessively used. In these cases, the goal is to provide an environmentally sound solution through degradation.

Luna is also working with Nancy Ornelas, a researcher at Tec’s Water Center, to develop strategies that help capture and break down microplastics produced from material that cannot be recycled.

These processes can be carried out through catalysis and chemical reactions involving nanoparticles and specialized materials that promote the reintegration of microplastics into nature.

In addition, Luna notes that the team is exploring circularity-based approaches for revaluing other types of plastic waste—not just PET, but also polyethylene (PE), polystyrene (PS), and PVC. These plastics are more difficult to recycle, but they can be chemically broken down into compounds useful to various industries.

“Today, we’re all thinking about recycling and reusing materials—that’s a crucial mindset. You don’t have to be a scientist or work in tech. If we start reusing plastics and reducing their use at home, I believe that, together with scientists and companies, we can make real progress in reducing plastic pollution,” says Luna.

Did you find this story interesting? Would you like to publish it? Contact our content editor to learn more at marianaleonm@tec.mx