Engineering and design students who will head management positions in the future will have an advantage: they will know about the potential and benefits of carrying out additive manufacturing processes, also known as 3D printing environments.

What is additive manufacturing?

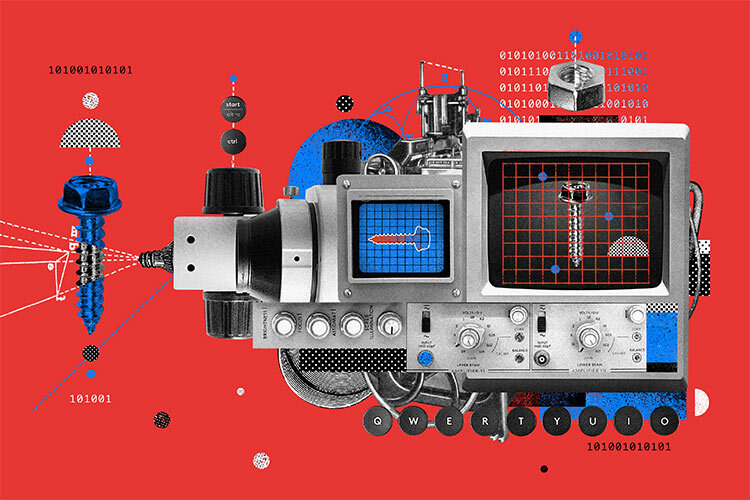

Additive manufacturing is a technology that uses 3D printing and is applied by many sectors of the industry to produce small parts, such as screws, since it allows reducing the cost of production when metal can be replaced by plastic.

Enrique Cuan Urquizo, professor at the School of Engineering and Sciences and researcher at the Institute of Advanced Materials for Sustainable Manufacturing of Tec de Monterrey, says that −almost two decades ago− this technology began to be known as the “rapid prototyping” process that allowed a material to be modeled layer by layer.

“We didn’t imagine how it would work,” he says in an interview with TecScience. “Studying the PhD, I met (3D printers) and today I have students who even have their printer at home,” he adds.

This technology began to leave laboratories since 3D printing allows reducing the cost of production when metal can be replaced by plastic.

It also allows the production of spare parts, without having an entire production line to manufacture hundreds of parts that may not be used in the market.

“It is no longer a technology accessed by certain experts in a laboratory. It is a technology that you can already buy”, comments Cuan Urquizo.

Differences between additive manufacturing and 3D printing

Science articles from the Massachusetts Institute of Technology (MIT) make a difference between “additive manufacturing” and “3D printing” which are used interchangeably but note distinctions between the two.

Additive manufacturing is the technological ecosystem of building physical parts and products from digital data while 3D printing is the process used to form an object.

Cuan Urquizo explains that students who take this course benefit from learning additive manufacturing basics and the 3D printing process, but they also discover how they can take advantage of this technology to drive innovative ideas.

“The generations that now have management positions in the industry are not familiar with (additive manufacturing). As long as the new generations occupy those positions, then companies will begin to trust this technology because young people have already been exposed to 3D technology”, says the Tec professor.

3D printing everywhere

Potential applications for additive manufacturing include aerospace, defense, and automotive materials. They have an important role in the medical sector in developing prostheses and even in the bioprinting of organs.

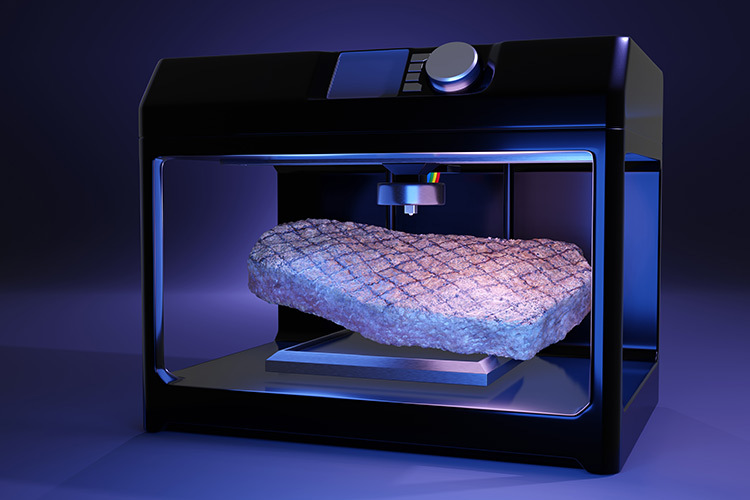

The food industry has also experimented with this technology to simplify food delivery logistics, extend shelf life, use new ingredients, and customized diets.

In the educational science article 3D printing: nice, but… how long does it last?, Cuan Urquizo wrote: “Today almost anything can be printed: airplane parts where you travel on vacation, dental molds to improve your smile, and sweets or chocolates for Valentine’s Day.”

The professor is currently involved in hip prostheses research. He is looking for the right material to achieve the right bio-performance of the prosthesis and good mechanical properties −resistance or flexibility− on the pieces that are printed.

“In biomedicine, the shape challenge implies that (the part) is required to be more comfortable or with the performance that is required. This is difficult to achieve with conventional manufacturing,” he stresses.

Design Based on Nature

During the Covid-19 pandemic, Professor Cuan bought a microscope with digital projection on his computer so he could see the microscopic composition of everything he found in his garden.

“Doing design based on Nature means that nature offers solutions to problems that engineers are facing, such as the optimal use of material”, he comments regarding his hobby.

“One of the advantages that additive manufacturing has is adding the material where you need it. Just as it happens in nature. If you see an wood organic design or look inside a bone, you see porosity combined with matter. Nature does not make mistakes. That amount of material used meets its objective”, he adds.

In the educational article Reticulated Materials Design: Science Inspired by Nature −co-authored with Armando Román Flores, director of the Mechatronics and Electrical Department of the School of Engineering and Sciences−, Cuan Urquizo offers a pleasant explanation about the “customized reticulated structures” with examples taken from nature like the wings of a fly.

He writes that during its flight, a fly can be exposed to strong mechanical loads, such as wind vibrations, and its wings will not bend.

Metal 3D printing

Tec de Monterrey is one of the educational institutions that has a 3D printing laboratory for metals. It is a printer capable of manufacturing components with stainless steel and titanium alloys.

Cuan Urquizo warns that there are different industries demanding metal manufacture to generate complex geometries. However, the most studied metal 3D printing uses metal powder.

“From the start, it is more dangerous because inhaling the dust is dangerous to health,” he highlights.

Printers that use polymers or plastics melt the material and add it in layers. On the other hand, the metal printing process involves solidifying the powder or sticking its particles with a laser.

Standards are needed to adopt 3D tech

“We are at a time when the industry must trust (additive) technology,” says Cuan Urquizo, who believes that Mexico pares other countries at the research level.

“What happens in other countries is that (industrial) developments go hand in hand with academic research. The industry is involved in these developments. In Mexico, they go separately. That creates mistrust that comes from misinformation,” he adds.

The researcher warns that there are outreach efforts so that the industry begins to learn about the potential of additive technology since only companies that have contact with foreign countries are familiar with these developments.

“Many things need to be standardized. An industry begins to trust a process when it is already standardized”, he says.