According to government data from the National Transplant Registry, more than 20,137 patients in Mexico were awaiting a transplant in early 2024, with only 1,302 done at the time, prompting research into alternative solutions from fields such as biomedicine, organ bioprinting, and chaotic printing.

The chaotic printing was developed by Grissel Trujillo and Mario Álvarez, the Tec de Monterrey research professors and leaders of the Alvarez-Trujillo Lab, along with other scientists and students who collaborate with them.

Trujillo exemplifies chaotic printing by forming structures similar to those seen while pouring liquid cream into coffee, resulting in diverse forms.

Contrary to its name, this sort of printing is predictable and controllable. It allows it to efficiently manufacture exact structures using mathematical calculations, perhaps paving the way for the printing of organs and tissues.

Chaotic Printing

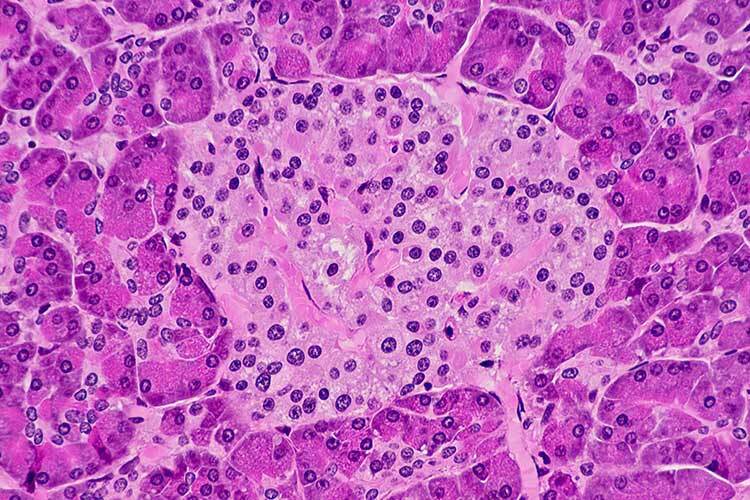

Unlike 3D printing, which creates structures by stacking materials, chaotic printing uses flows of viscous materials that are injected to produce structures that resemble human tissues.

Grissel Trujillo explains Mario Álvarez’s work inspired her in the chemical sector, where he used very viscous fluids to form combinations in a slow, simple process.

These circumstances are ideal for organ and tissue bioprinting since caution is required to avoid harming the injected cells.

“Cells must be handled with extreme caution, or they will die. So, with other printing methods, to create very thin layers, cells must be supplied through a very small needle, which puts a lot of stress on the cells and causes them to die,” adds Trujillo.

“These structures are generated at a microscopic size; therefore, they are exceedingly small and detailed, with ideal interior architecture”, adds the researcher.

Another feature of chaotic printing is that the produced structures are compatible with cells and biological materials, making them suitable for printing since they are made swiftly and precisely, which are critical factors in producing living tissues.

Applications of Chaotic Printing

This research has the potential to impact various sectors, including regenerative medicine, therapeutic and pharmaceutical development, and even food production.

The capacity to create customized tissues for transplantation may reduce dependency on organ donors and improve the compatibility of some transplants.

Similarly, it may be possible to print small human tissues to evaluate the efficacy and safety of new drugs, thus reducing the need for animals in pharmaceutical research.

Another use for chaotic printing is creating alternative meals, such as lab-grown beef. Trujillo says that printing skeletal muscle tissue might provide a sustainable alternative to traditional meat production, lowering the requirement for animal breeding and reducing its environmental impact.

Trujillo, Álvarez, and a group of entrepreneurs founded Forma Foods. This startup prints meat by taking a biopsy from livestock, isolating stem cells in a bioreactor, multiplying them, and stimulating them to create skeletal muscle with nutrients and flavor similar to traditional meat.

“I say it, but so do my colleagues from other areas: this can revolutionize the game in bio-manufacturing and bio-printing. We should be happy that it is a Mexican-made technology produced by Latin American researchers and students from Tec de Monterrey,” Trujillo stated.