Dairy whey is the liquid left over after turning milk into other products like cheese and butter. It is commonly thrown away without knowing that it includes around 20% of the protein from the original milk as well as other healthy ingredients.

The situation has generated discussions and new ways to use dairy whey, also efforts to change people’s and businesses’ perceptions of its use and nutritional worth.

The panel “Technological Alternatives for Dairy Whey Utilization” was held during the workshop “Dairy Products and Alternatives for By-Products Use: Nutrition and Sustainability,” organized by the Institute for Obesity Research.

During the panel, the researcher Ángela Suarez from the Center for Research and Assistance in Technology and Design of the State of Jalisco (CIATEJ), from the National Council of Humanities, Sciences, and Technologies (CONACYHT), Bertha Montalvo from the company Sigma, Enrique Romo from U.S. Dairy Export Council USDEC and Hugo Cruz from the Nestlé company.

The event took place at Tec de Monterrey in cooperation with its Institute for Obesity Research and the Institute of Dairy Products of Asturias (IPLA) in Spain. Researchers and business representatives from dairy product manufacturers like Sigma, Yakult, Nestlé, and Alpura have also participated.

Dairy whey have evolved over time

One of the key subjects explored on the panel was the concept of dairy whey throughout history.

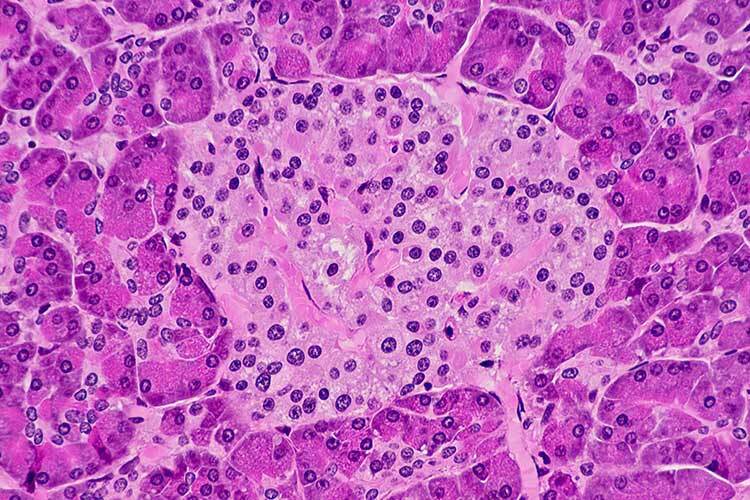

Whey was considered a leftover product from the making of cheese, even when it made up around 90% of the weight of the milk.

Research and technical advancement did not make individuals and industries aware of its nutritional worth and potential for human consumption until the 1960s. There are still some consumers who refuse to see its advantages, despite these advancements.

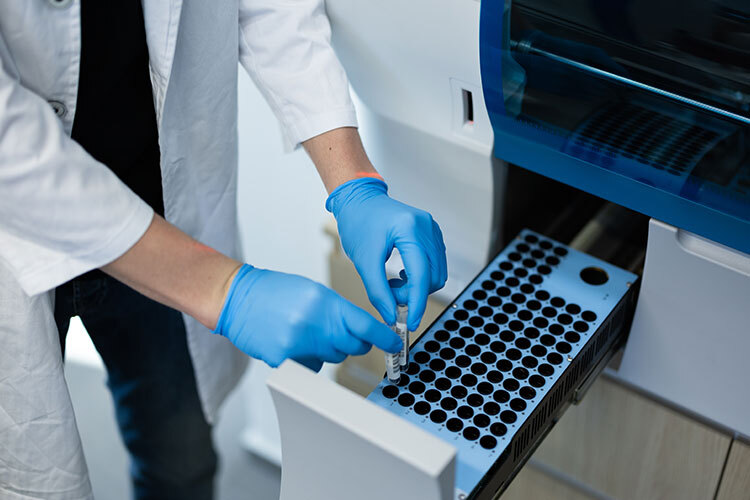

Dairy whey is very perishable and needs refrigeration for processing and transit, making recovery and storage difficult, especially for small and medium-sized businesses.

Logistical issues in transit from production facilities to processing plants must also be solved, to guarantee the quality of products derived from whey, such as drinks, proteins, supplements, or even newborn formulas, among others.

“At Nestlé, we use whey primarily for infant formulas, and for these products, the quality standards must be very strict,” said Cruz.

Sustainability is another technological difficulty since, if thrown improperly, whey may be extremely polluting.

The use of whey presents an opportunity for these dairy firms as more and more of them pursue ecologically friendly approaches.

“Discarding it causes a significant environmental issue, but you’re also throwing away an important and useful substance. We must create procedures for manufacturers, particularly medium- and small-sized ones,” stated Enrique Romo.

Changing opinions about dairy products

The panelists also talked about how whey-derived goods must be introduced to the market while taking into account the desires and requirements of customers.

The ability to employ whey-derived products with high nutritional content to discover solutions to social issues like poverty or hunger in Mexico is another opportunity itself.

One of the ideas mentioned during the event is working with governmental organizations and disadvantaged populations to first comprehend their unique requirements and then develop solutions that are targeted to them.

Other ongoing problems in the dairy sector involve developing products that satisfy consumer demand and raising public awareness of lactose intolerance and allergy.

Experts emphasize the need for simple, basic advertising techniques that don’t mislead customers and provide them with the information they need to make informed decisions.

Working with governments to guarantee optimal whey use in relation to public policies, laws, and needs for healthful components in dairy-origin products is an additional opportunity.

Whey can be utilized by some businesses in a variety of processes, including fermentation and the manufacture of alternative proteins, opening up new possibilities for its use.

The panelists highlighted the need of encouraging collaborations with businesses or cooperatives to increase the production of these goods and avoid whey being wasted.

“We acquire and process liquid whey. We have a high volume of purchases in Mexico, which helps little and medium-sized cheese producers who can’t afford this equipment, added Cruz.

Bertha Montalvo also emphasized the requirement for standardizing whey procedures and seeking uniform regulations among most whey providers.

Montalvo concluded: “Having these alliances between various companies becomes essential because it improves the relationship between ingredients and production.”