The partnership between science and industry can be a symbiosis: both participants obtain a benefit from the association and create innovative products, with a positive impact on society.

An example of the advantages of this is the collaboration –which was born six years ago– between researchers from Tec de Monterrey and Alpura, the Mexican company that creates dairy products.

“We have opted for a long-term relationship, to create knowledge and cutting-edge technology in the generation of dairy products,” says Jorge Welti Chanes, research professor at the School of Engineering and Sciences (EIC) at Tec de Monterrey and leader of the cátedra Alpura, in an interview with TecScience.

Cátedra Alpura is the official name given to the alliance, in which researchers from the Biotechnology Center, the Emerging Technologies Laboratory, the Protein Research and Development Center and the Water Center for Latin America and the Caribbean have participated. The area at Alpura that participates is its Research and Development Center (CIDEA).

Alpura PROtein Milk

One of the fruits that this relationship has yielded is the generation of Alpura Pro, a cow milk enriched with 70% more protein and 60% more calcium, which is now available on the market.

To create it, researchers applied membrane separation technology to retain the proteins and calcium present in the milk, accumulated them and then returned them back to it, thus increasing the amount available of both nutrients.

“As they come from the same components of milk, this facilitates absorption by the human body,” explains Zamantha Escobedo, research professor at the EIC, in an interview.

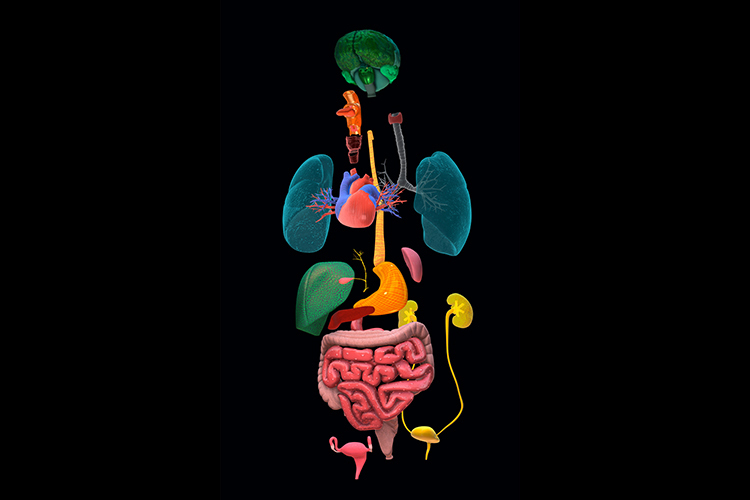

With this product, they contribute to improving the health of Mexicans. Proteins are nutrients necessary to give us energy and strengthen our muscles and skin.

Calcium is one of the most important minerals for the human body. It helps keep teeth and bones strong, helps with brain signaling, and maintains heart rate.

To confirm that it is indeed enriched in protein and calcium, the amount of these is measured in a certain volume of the treated milk and compared with one that has not been modified with the technology.

“This way, we make sure that it will have a positive effect on the health of consumers,” says Escobedo.

Pasteurization Without Heat

Another project that has emerged from this association is the generation and application of emerging technologies to pasteurize milk without using heat.

Pasteurization is the process by which pathogens, such as bacteria, yeasts and molds, are eliminated from dairy foods. The traditional way to do it is subjecting the product to temperatures above 60° Celsius.

This ensures that the product is safe for human consumption, but it also removes vitamins and nutrients, changing its flavor and texture.

“If we compare the taste of modern milk with raw milk, they are two completely different flavors; we no longer know what the original milk tastes like,” says Welti.

To solve this, Tec researchers have used electrical energy, light, and high hydrostatic pressures to damage the membranes of microorganisms and deactivate them.

To achieve this, it was necessary to study biochemical, physical, thermodynamic and engineering processes.

“The goal is to have products that are just as safe for consumption but have better nutritional and sensory quality, with a less processed flavor, so to speak,” explains Escobedo.

In addition, replacing heat with other technologies helps reduce the negative impact the dairy industry can have on the environment.

The goal of Tec researchers involved in this project is that these technologies are eventually patented and recognized as an official alternative to thermal pasteurization.

A Win-Win Alliance

According to Zamantha Escobedo, when the industry seeks to collaborate with researchers, it can help them be more competitive through the development of evidence-based processes and innovative products.

Also, it helps support products scientifically, generating safe technologies and foods for consumers. “By connecting with us, they can benefit society more,” says the researcher.

Welti-Chanes believes that academic institutions can benefit from association with industries too, because the resources they provide can be used to develop research in other fields.

Currently, the Mexican government has dedicated less than 0.3% of the Gross Domestic Product (GDP) to science and technology, so financing alternatives are needed.

Also, with the financial input from the industry, the training of human resources can be supported. From this collaboration, various scientific articles have been generated, and multiple master’s, doctoral, and postdoctoral students have graduated.

“I am a believer that research is best done in groups, which is why these collaborations are so important,” says the expert.

These alliances can encourage research generated by universities to be applied more quickly for the good of humanity.

“The main beneficiary will always be the consumer and society. These products and technologies must be designed to improve the way we live,” says Escobedo.

The Future of the Tec-Alpura Collaboration

In the future, their vision is to work on achieving minimal processing of dairy products so that they require fewer interventions without sacrificing safety.

Also, they seek to reduce the impact of food industries on the environment, using new technologies to modernize them.

The byproducts generated in the production line can generate others and thus reduce waste.

“To the extent that the government and industries support research, knowledge to make countries more competitive and innovative can be generated,” says Welti.