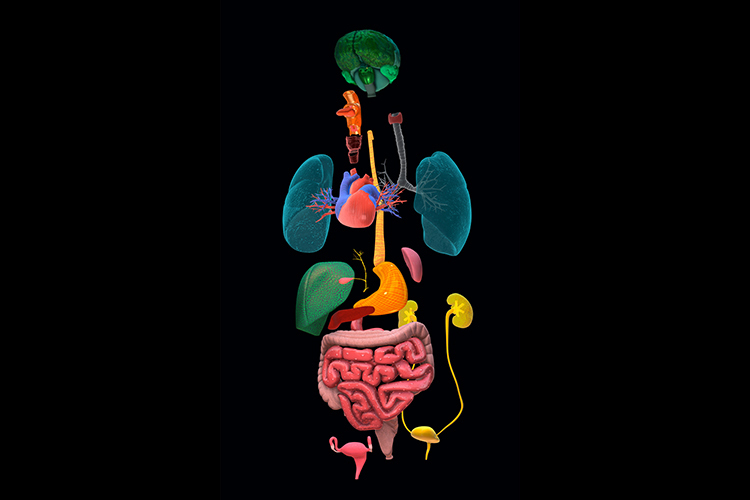

3D anatomical models have been around for many years. We’ve all likely seen one in a classroom to learn how our internal organs are arranged. However, they miss one detail: their rigidity doesn’t reflect the reality of human tissue. Now, additive manufacturing can make them soft…and incredibly lifelike.

Creating organ models with millimeter precision that replicate the texture and feel of real organs emerged a few years ago at the School of Engineering and Sciences (EIC) and the School of Medicine and Health Sciences (EMCS) at Tec de Monterrey. However, it couldn’t materialize until recent technological advancements made it possible.

The idea has become a reality through a multidisciplinary and multi-institutional effort involving biomedical engineers, materials scientists, imaging experts, and doctors. Surgeons and medical students alike can now use these models.

Their applications range from rehearsing surgeries to minimize errors to testing medical devices —like an arterial stent— before they’re placed and training future doctors.

“Maedditiva was born out of the need to apply additive manufacturing to medicine. The name itself is a combination of these concepts,” says Alan Aguirre, the lead researcher of the Macromolecular and Photosciences Research Group and a professor at the EIC, in an interview with TecScience.

Together with Elnaz Hosseinzadeh, a postdoctoral student in the Nanotechnology Graduate Program at the EIC, and Alejandro Fabiani, a vascular surgeon at Zambrano Hellion Hospital, TecSalud, Aguirre co-founded Maedditiva, a science-tech-based company, on February 14, 2024—a new reason to celebrate Valentine’s Day.

Maedditiva: Beyond 3D Printing

While additive manufacturing —commonly known as 3D printing— is widely discussed today, achieving what Maedditiva has is no small feat.

In these technologies, there are various printing methods, and the one you choose determines what materials can be used and the final result.

“If you want to create flexible models that closely mimic real tissue, you need very specific processes and materials that not everyone is familiar with or knows how to use,” says Hosseinzadeh.

In their case, they use a process known as photopolymerization, where a liquid substance —in Maedditiva’s case, resins— is exposed to light from lasers or LEDs, triggering a chemical reaction that solidifies it.

“We encounter these materials and reactions in our daily lives, like sealants that start as liquids and then harden,” explains Aguirre.

The printer builds layers of this reaction until the final model is created, with a soft, flexible, yet firm consistency, just like a real organ.

In the more popular type of additive manufacturing, a process called FDM is used. In this process, a solid material is melted to build up layers, resulting in a hard material with visible lines. Photopolymerization allows these layers to be seamless and undetectable.

In addition, the team developed a coating that makes the final pieces transparent, allowing you to see the internal structure of a complex organ, like the heart.

“It’s like the final layer used in a manicure, but it’s flexible and doesn’t restrict the material’s final properties,” says Hosseinzadeh.

After printing, various steps are required to make them transparent. They also need to be washed and cleaned to achieve the final product. All this requires skilled hands and minds.

From Medical Images to 3D Models

To replicate the anatomy of an organ, the team uses medical images —like CT scans, X-rays, ultrasounds, or MRIs— which are fed into the only software approved by the U.S. Food and Drug Administration (FDA) that translates them into a 3D model. This approach allows them to print, with great precision, the organ of a specific patient.

“We all have veins of different sizes, and the morphology of organs varies significantly between people,” Aguirre notes.

Printing them with a person’s specific characteristics can help reduce the margin of error in surgeries, as doctors can practice on an almost identical model.

“When you hold one of these prints, it feels like touching a real artery—it’s a huge leap forward,” Fabiani adds.

Today, medical errors are a significant cause of death and injury worldwide. In the United States, a recent study found that around 250,000 people die each year due to these errors.

Moreover, they can also be printed with an aneurysm or tumor. “If I have to reach a tumor located at the back of a liver to remove it, you can print one similar to the real thing, allowing me to see how to navigate through the organ to get there,” says Fabiani.

Anatomical Models for Training Future Doctors

These models can also be used to train medical students, teaching them everything from how to give a painless injection to performing high-complexity surgeries.

”You can practice as many times as needed to get it right before performing it on a patient,” explains Fabiani.

This type of training is not only particular to the human body but could also reduce the use of animal models in education.

”I believe this could largely replace the need for training on non-human animals,” says the cardiothoracic surgeon.

Medical interventions, like placing a stent in a blood vessel, can also be tested to model how much wear they will endure and what materials are required for optimal function.

The ‘Uber Eats’ of 3D Anatomical Models

So far, their models have been used to prepare for 13 surgeries at Zambrano Hellion Hospital. Two models have been sent to Brazil, and around seven have been sent to the Technical Medical Centre at the University of Twente in the Netherlands.

“At Zambrano, they have been primarily used in surgeries to treat abdominal, femoral, and thoracic aneurysms in adults,” says Aguirre. In Brazil, they connected a cardiac model to a pumping system to simulate blood flow through the veins and heart.

Additionally, the technology behind the coating that makes the models transparent and flexible is being patented. They are also planning to develop an app that allows to order models on demand. “It’s going to be like the Uber Eats of 3D anatomical models,” says Hosseinzadeh.

Over time, they hope to establish the company as the go-to resource for doctors and surgeons when they need realistic organ models with diverse applications.

“We’re here to provide a service that understands the specific needs of each application within the medical field and knows how to connect them with material development.”

Interested in this story? Want to publish it? Contact our content editor to learn more: marianaleonm@tec.mx