Mexican researchers are developing a new technology that helps replace or regenerate damaged bones in diabetic patients, potentially preventing the loss of limbs.

These are 3D-printed bone scaffolds, designed with special structures and materials that mimic the behavior of real bone. They replicate key characteristics of bone tissue, such as shape, porosity, and stiffness.

This line of research began over five years ago when a team worked with a patient who had already undergone an amputation. The goal was to develop sensor-equipped, comfortable prosthetics, explains Erick Guadalupe Ramírez, a researcher and director of the Innovation and Transformation program at the School of Engineering and Sciences at the Monterrey campus.

That’s when Josué García, a mechatronics engineer trained at Stanford University and Tecnológico de Monterrey, decided to tackle the problem much earlier—at the stage when diabetes begins to damage bone tissue and the risk of limb loss becomes real.

In Mexico, the leading cause of amputations is diabetes. People with the disease are 15 to 30 times more likely to lose a limb compared to those without it. Infections from ulcers and soft tissue damage are among the various causes that can lead to amputation, as are issues with bone tissue, such as fractures that fail to heal.

Mechatronics and Engineering Focused on Health

“It’s a team effort involving experts in design, manufacturing, materials, and surgery. Surgeons are beginning to see the possibilities that new technologies can offer,” he explains.

That’s how the idea emerged to develop grafts that could serve as replacements for parts of bones that have degenerated.

“It was a powerful motivation to focus on diabetes as a disease and recognize that we can use engineering for the benefit of humanity,” he says. “When someone has this condition, it triggers changes in the body, such as increased bone porosity, which makes them more likely to suffer fractures.”

What Are Artificial Bone Scaffolds and How Are They Made?

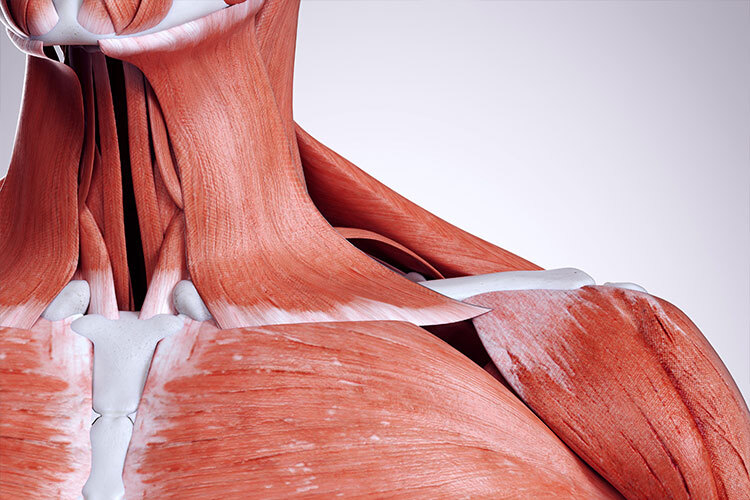

The researchers focused on developing artificial bone scaffolds using advanced additive manufacturing techniques. For García, this is a way to contribute to the field of regenerative medicine by creating bone substitutes.

To achieve this, they designed a structure based on geometries known as TPMS (Triply Periodic Minimal Surfaces), which mimic the internal structure of bones. These patterns resemble those found in sponges or honeycombs, allowing the scaffold to be both strong and lightweight. The geometry can be adapted to different parts of the body, and its nature facilitates the regeneration of damaged bone by encouraging cell growth.

As for the process of developing these bone scaffolds, it begins with a CT scan of the patient, explains Ramírez. Using that data, they reconstruct the bone in 3D and design a custom-made scaffold.

“CT scans are a standard procedure in hospitals, but we generate 3D files from them so we can analyze the structure,” he adds. “One of the advantages of additive manufacturing is that we can create complex shapes that wouldn’t be possible with traditional methods. So we combine the intricacy of the human body with what manufacturing technology allows us to do—plus extra components like hydroxyapatite and other elements that speed up bone regeneration.”

Hydroxyapatite and calcium phosphates are materials naturally produced by the body—they’re found in teeth and bones. But under conditions like metabolic disruptions caused by diabetes, they may not be sufficiently present in certain areas of the bone. That’s why they’re externally or artificially incorporated into the scaffold material, he explains.

Digital Manufacturing: Precise and Fast

What makes this proposal innovative, according to the researcher, is that the team has access to digital manufacturing tools that allow them to create custom bone scaffolds with greater precision and in significantly less time.

Depending on the specific needs of the patient and the medical team’s recommendations for the case, they design a tailored scaffold. They then conduct dynamic studies, including biomechanics—to gather data on how a person moves while walking—and structural load analysis.

“We use mechanical simulation software to analyze how forces are transmitted through the body’s structure and how they directly impact the implant we’re designing,” García explains. “Based on the dynamic data we collect, we run mechanical simulations of the implants to understand how they perform under those mechanical loads.”

Exploring Other Conditions

Ramírez emphasizes that the project is a multidisciplinary effort, with his research being complemented by other fields related to the study, such as biomaterials synthesis, as well as medical and biological aspects.

While still in the exploratory phase, the ultimate goal is to develop an application that not only benefits diabetic patients but can also be adapted to help people with other medical conditions.

“Right now, we’re focusing on fracture cases related to diabetes, but this technology could also be applied in situations involving cancer, where bone reconstruction is needed or where a bone affected by sarcoma has to be removed,” he explains.

Did you find this story interesting? Would you like to publish it? Contact our content editor to learn more: marianaleonm@tec.mx.