By José Antonio Torres, Jorge Welti-Chanes and Enrique Martínez

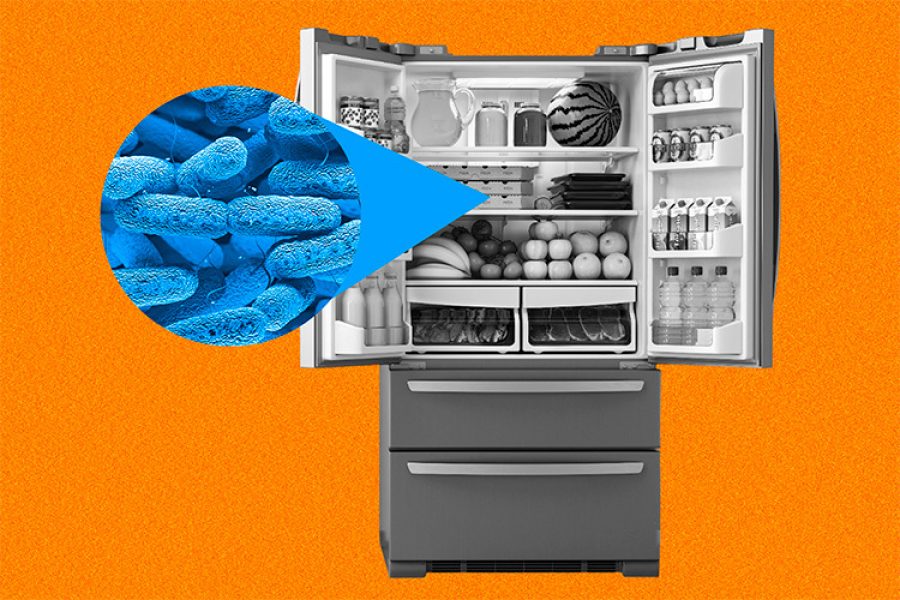

The refrigerator is an indispensable household appliance for keeping food fresh longer and reducing waste. But how do we know whether it is actually working optimally?

An estimated 85% of households worldwide own a refrigerator, making it a cornerstone of modern living. In China, for example, consumers spend around $14 billion a year replacing old refrigerators [1]. If that figure is extrapolated to the United States, annual spending would reach about $7.3 billion, and in Mexico, it would be close to $2 billion.

What is far less discussed, however, is that in an effort to reduce their environmental footprint, refrigerators are increasingly designed to prioritize energy efficiency—often without fully considering how those design choices affect proper food preservation.

Cold—But Not Cold Enough

Many consumers assume their refrigerators are working properly because they can feel a clear difference between the room temperature and the temperature inside. But that perception is misleading—and not enough.

Global studies show that 77% of refrigerators operate above the 4°C (39°F) recommended by health authorities, in some cases reaching as high as 20°C (68°F), even in developed countries [2]. These conditions of “temperature abuse” directly contribute to food waste: on average, each person throws away about 79 kilograms (174 pounds) of food per year.

The impact is enormous. Valuable resources are lost, food safety is compromised, and economic costs rise for both consumers and the food industry [3].

The problem can be traced to two main factors: (1) refrigerator design, which is focused almost exclusively on meeting energy-efficiency regulations, and (2) improper user practices in food handling and storage.

A Smart Ally: RPI

In our work, we aim to develop a computational tool that helps manufacturers design refrigerators with better food-preservation performance, while also allowing consumers to understand how their usage habits affect the quality, safety, and waste of the food they store.

This tool is the Refrigerator Performance Indicator (RPI), a system that uses time–temperature data together with predictive microbiology models to estimate how the presence of microorganisms in food increases depending on storage conditions.

An RPI value below 1 indicates excellent preservation; a value close to 1 reflects acceptable preservation; and values above 1 signal poor refrigerator performance.

In addition, the RPI enables assessment of how other factors—such as compressor type, door-opening frequency, food load, and ambient temperature—influence overall performance.

What the Results Show

When fresh panela-style cheeses were analyzed to assess the performance of different refrigerators using Listeria monocytogenes predictive models [4], the results showed that units equipped with modern, variable-speed compressors—designed to consume less energy—performed worse at preserving food than those with conventional compressors.

This difference was particularly noticeable under high ambient temperatures and when the refrigerator was fully loaded, highlighting how energy-efficient designs can sometimes compromise food preservation.

The analysis also showed that each time the door is opened, the internal temperature rises and the cooling recovery process is delayed, undermining food freshness.

The Future of Smart Refrigeration

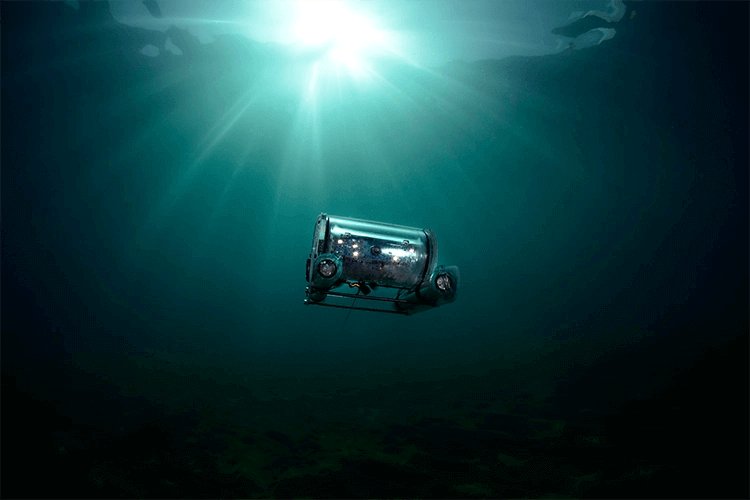

RPI offers a promising way to balance energy efficiency with effective food preservation. The next step is to combine it with emerging technologies such as the Internet of Things, which would allow refrigerators to connect to the network to send and receive data in real time, and machine learning, capable of analyzing that information to anticipate failures or suggest improvements.

Another key development is so-called digital twins—virtual models that act as a “clone” of the refrigerator, simulating its performance in order to test adjustments without intervening in the physical appliance. This can be complemented by image-processing technologies that could identify which foods are inside the refrigerator and assess their state of preservation.

If these innovations are integrated into the intelligent systems of modern refrigerators, the RPI could monitor appliance performance in real time. With this information, consumers would be able to modify their habits to preserve food more effectively, reduce waste, and contribute to global food security.

References

- Slotta, D. (2024). Number of refrigerators per 100 households in China 2022, by region.

- James, C., Onarinde, B. A., & James, S. J. (2017). The use and performance of household refrigerators: A review. Comprehensive Reviews in Food Science and Food Safety, 16(1), 160–179.

- United Nations Environment Programme. (2024). Food Waste Index Report 2024.

- González de la Garza, D., Martínez-Martínez, E., Fernández Villanueva, G., de la Cruz Quiroz, R., Rodríguez-Martínez, V., Fagotti, F., Welti-Chanes, J., & Torres, J. A. (2024). Assessing refrigerated preservation performance using Listeria predictive microbiology models and temperature data: Refrigerator performance indicator and time-temperature equivalent. Journal of Food Science, 89(9), 5812-5822.

- Martínez Martínez, E., Cortés, A. G., de la Cruz Quiroz, R., Alejandro, J. G. R., Fagotti, F., & Torres, J. A. (2024). Microbial Preservation Performance of Cold Storage Units Assessed by Modeling of Time–Temperature Data. Food and Bioprocess Technology.

- Rodriguez-Martinez, V., Velazquez, G., Massa-Barrera, S., Welti-Chanes, J., Fagotti, F., & Torres, J. A. (2019). Estimation of Safety and Quality Losses of Foods Stored in Residential Refrigerators. Food Engineering Reviews, 11(3), 184-199

Authors

José Antonio Torres is a professor at the School of Engineering and Sciences at Tecnológico de Monterrey and holds a Ph.D. from MIT. He has authored more than 200 publications in engineering and food microbiology. His research focuses on nonthermal processing, probabilistic applications, and energy efficiency in food preservation and distribution.

Jorge Welti-Chanes is a research professor in Biotechnology and Food Science and has served as National Director of Graduate Studies and Associate Academic Dean at the School of Engineering and Sciences at Tecnológico de Monterrey. He is the author of more than 240 scientific papers, 85 book chapters, and 17 books, and is the founder of two companies, all in various areas of engineering and food processing.

Enrique Martínez Martínez focuses his research on predictive modeling and optimizing food preservation throughout the cold chain, with expertise in process optimization and emerging technologies. He has collaborated with TU Berlin and the National Mango Board and has published multiple Q1 and Q2 journal articles on food preservation and quality. He is a professor at the School of Engineering and Sciences at Tecnológico de Monterrey.