You’ve finally made it. You’ve arrived at the beach for a well-deserved vacation. You slip off your sandals, dig your feet into the sand, and even play with it between your toes. Then, out of the corner of your eye, you spot a dark patch in the water, gently drifting with the waves until it piles up along the shore in little mounds.

Curious, you walk over to take a closer look and realize it’s seaweed. It’s starting to decompose and gives off a faint smell of rotten eggs. This is sargassum, the environmental problem you’ve probably heard about in the news—and as unsightly as it may be, it has the potential to become a valuable resource.

What Is Sargassum?

Sargassum has been washing up on the shores of the Mexican Caribbean for many years. Still, in 2011, the massive influx of this macroalgae began to escalate into a serious issue—one that now affects not just tourism and the local economy, but also the environment and marine ecosystems. On top of that, it poses a public health risk, potentially causing respiratory, cardiovascular, and neurological problems.

“It’s not just an issue of beach aesthetics or whether people can swim. This is a complex ecological phenomenon tied to changes in ocean currents, rising sea temperatures, and increased nutrient levels in the water. We need to find cost-effective solutions that allow us to collect and process it,” says Danay Carrillo Nieves, a researcher at the School of Engineering and Sciences and head of the Carrillo Biorefinery Lab at Tec de Monterrey’s Guadalajara campus.

The seaweed washing up in Mexico primarily consists of two species: Sargassum natans and Sargassum fluitans. It originates in the Sargasso Sea, located north of Bermuda—yes, the very same area known for vanishing ships—and is carried by ocean currents. This means it travels across the Atlantic, circling multiple regions—including Africa and South America—before reaching the Mexican Caribbean.

Sargassum has tough cell walls and is considered recalcitrant, meaning its structure is especially difficult to break down.

Moreover, sargassum often carries heavy metals like arsenic, aluminum, and copper, limiting its potential as a raw material. If not managed properly, it can contribute to beach erosion, interfere with sea turtle nesting, and block sunlight from reaching underwater ecosystems, harming coral reefs.

Researcher Danay Carrillo Nieves first encountered this seaweed during her childhood in Cuba, when she would come across a few stray strands on the beach and simply toss them aside when they got in her way.

But in 2018, while on a family trip to Cancún, she saw that those few little strands had multiplied into large floating masses, so dense they kept her from even getting into the water.

As a chemical engineer, she began thinking about how this decaying plant matter might be releasing gases like ammonia and hydrogen sulfide—both of which are toxic to humans.

Possible Solutions for Sargassum

Carrillo’s interest in finding value in sargassum led her to design a project to study it and explore ways to give it added value. She submitted a proposal and won a grant from the National Council of Humanities, Sciences and Technologies (Conahcyt) and CONTEX (a joint initiative between the Texas University System and the Mexican government) to develop strategies for reducing its impact.

Carrillo and her colleagues use biorefinery techniques to convert organic materials into valuable resources. They’re researching to isolate bioactive compounds found in the macroalgae—such as alginate, fucoidan, and fucoxanthin, as well as polyphenols and laminarin—with potential applications in the pharmaceutical, food, cosmetic, and agricultural industries.

In addition, the biomass and resulting waste can be processed to produce biogas and biofertilizers, allowing for the full use of sargassum with zero waste.

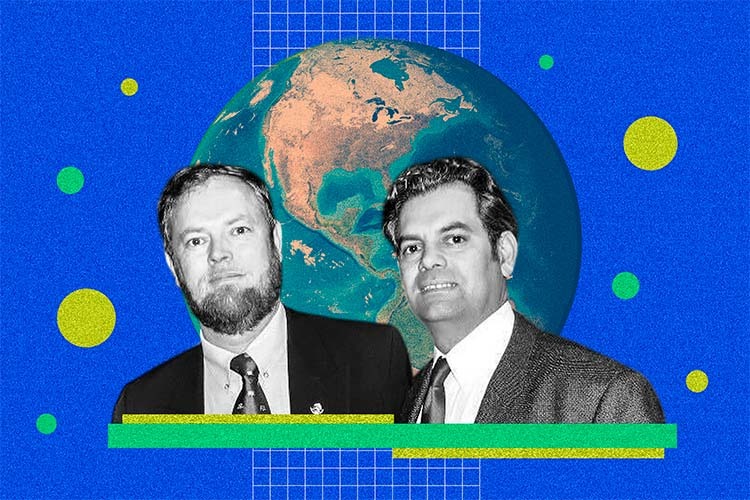

At Tec de Monterrey’s Guadalajara campus, a team led by researchers like Tomás García Cayuela is working on environmentally friendly methods for extracting these compounds. The goal is to ensure that the solution doesn’t create an environmental impact equal to or worse than the problem itself. That means avoiding harsh chemical solvents and instead using techniques like ultrasound or ethanol-based extraction.

Scientists from Other Universities Join the Challenge

Raúl Tapia Tussell, lead researcher at the Renewable Energy Unit and Director of Technology Management at the Scientific Research Center of Yucatán (CICY), is also part of this nationwide effort, coordinated by the Secretariat of Science, Humanities, Technology, and Innovation (Secihti). The initiative brings together several institutions—such as Tec de Monterrey, the National Autonomous University of Mexico (UNAM), the National Polytechnic Institute (IPN), the Autonomous University of Coahuila, and the Center for Research and Assistance in Technology and Design of the State of Jalisco (CIATEJ), among others—to tackle the sargassum problem sustainably.

Thanks to numerous studies, scientists now have a better understanding of the characteristics of Mexican sargassum. For example, in 2021, Tapia and researchers at CICY led a project—funded by the Mexican Navy and Conahcyt—to analyze its chemical composition and the presence of heavy metals.

They collected samples from various locations along the coast—on the beach, five meters offshore, and in open water—to conduct their analyses. The findings have helped inform decisions on how to manage sargassum, whether as a potential raw material or as a hazardous waste.

Building on that research, the team is now working on a sargassum depolymerization project. This oxidative process breaks down the rigid outer cell walls of the algae, much like cracking open a nutshell. This allows them to access the internal compounds and reduce the concentration of heavy metals.

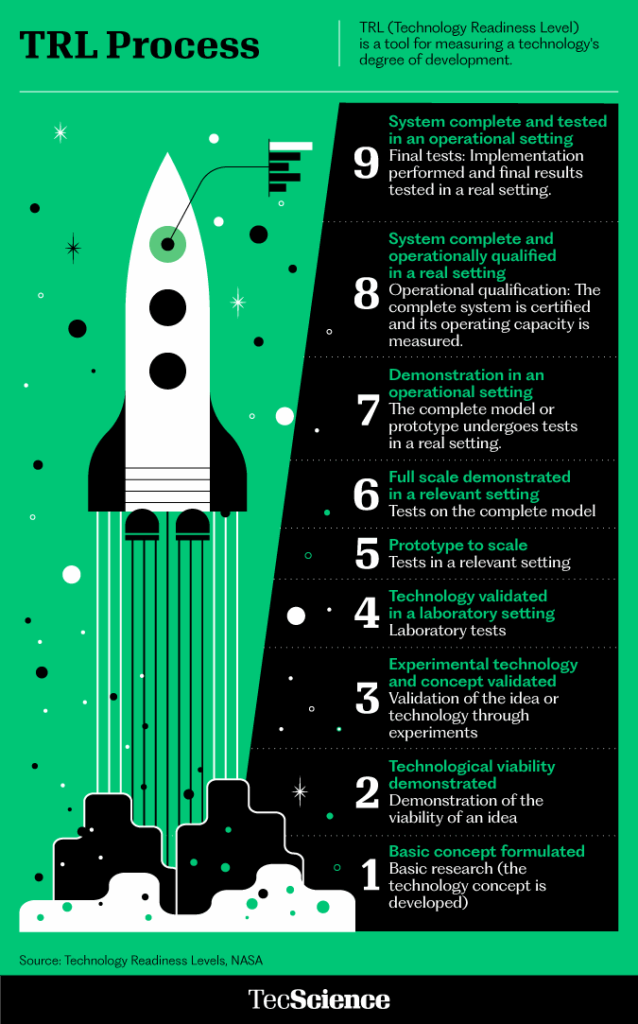

This project has already reached a high level of technological maturity and is ready for larger-scale pilot testing.

With the processed material, Tapia Tussell is exploring a range of applications: producing biogas from organic waste through anaerobic digestion; extracting sodium alginate for use in the cosmetic, pharmaceutical, industrial, and food sectors; and creating “plastic wood” by blending it with recycled plastics to manufacture items like flooring, plant pots, and moldings.

This last approach not only helps control the sargassum problem, but also provides an alternative for reducing plastic waste—aligning with a circular economy model.

Using Sargassum as a Water Filter

José Luis López Miranda is one of the researchers at the Center for Applied Physics and Advanced Technology at UNAM’s Juriquilla campus in Querétaro. He works with Miriam Estévez González’s team to harness the unique properties of sargassum and transform it into sustainable products and resources for use in areas like water treatment and construction.

To get the most out of the algae, the team needs it to be collected fresh—before it washes ashore and begins to decompose—so that it retains its useful properties.

They collaborate with a team from UNAM’s Institute of Marine Sciences and Limnology in Puerto Morelos, Quintana Roo, which uses special boats to scoop up the algae while it’s still floating at sea. The collected sargassum is then spread out to dry in the sun, stored in bags, and packed in boxes for transport to the lab, where it can be safely kept for up to two years without the need for special preservation conditions.

One of the applications this team is developing is a cost-effective, sustainable water filter that takes advantage of sargassum’s natural ability to absorb pollutants. In essence, it acts like a sponge, trapping heavy metals like mercury, cadmium, and lead; industrial dyes; and pharmaceuticals such as paracetamol and diclofenac.

“We treat it so that it releases all those metals, metalloids, and so on, and dispose of them properly,” explains López. “That way, we can really make the most of the sargassum and say, hey, it’s not all bad. We process it to make it suitable for our needs. We activate or functionalize it so that it binds specifically to the molecule or substance we want to remove.”

The researchers have conducted tests using various mixtures of contaminated water and measure how much the concentration of pollutants decreases after passing through the sargassum filter. The seaweed can be used either chopped or ground, depending on the size of the particles they’re targeting. Currently, the team has developed filter prototypes in the shape and size of cartridges compatible with standard commercial filtration systems.

And for Construction Panels

Another project aimed at repurposing this macroalgae focuses on the construction industry—specifically, the production of interior panels made by combining sargassum with other materials like gypsum.

The researcher explains that the resulting product, dubbed the “Sargapanel,” has mechanical strength comparable to that of conventional panels, along with thermal and acoustic insulation properties. It also has a flame-retardant effect, which enhances safety in the event of a fire.

The team is also looking to leverage this flame-resistant property to produce paper and cardboard that can be used for making boxes and packaging—offering a biodegradable alternative with added fire resistance.

A Collective Effort

Although more research is needed to fully bring these various solutions to life, López emphasizes that no single sector can solve the sargassum problem alone. Collaboration between academia, industry, and government is essential.

“Industry won’t commit unless it sees a clear and viable outcome,” he says. “That’s where government agencies could step in—to provide funding or support to turn these projects into actual products. We need everyone at the table.”

For Danay Carrillo Nieves, sargassum is more than just a nuisance—it’s a reminder that creativity and collaboration can transform any crisis.

“Let’s not always see things in life as problems. Not everything is. Let’s try to look on the bright side—what might seem bad at first glance could have hidden value. I truly believe that’s what we’re seeing with sargassum.”

Were you interested in this story? Want to publish it? Contact our content editor to learn more: marianaleonm@tec.mx