By Reyna Berenice González González y Pablo Alfredo Sánchez Pineda

Plastic production has become an ever-growing problem. It is expected to triple by 2060; unfortunately, only 9% of this waste is recycled [1,2]. This material has increasingly been found within our food chain and micro-ecosystems, raising concerns about potential impacts on human health.

New alternatives have emerged in recent years, including organic and biodegradable materials. Biodegradable biopolymers, such as polyhydroxyalkanoates (PHA), polyhydroxybutyrate (PHB), and polylactic acid, are produced from renewable sources and can naturally decompose in the environment, offering ecological advantages.

Sugars, proteins, and microorganisms are among the sources used to produce these biopolymers. Microorganisms, in particular, have garnered significant interest due to their rapid growth capacity, abundance in nature, low energy consumption, and potential simultaneous applications in water treatment and the production of other resources.

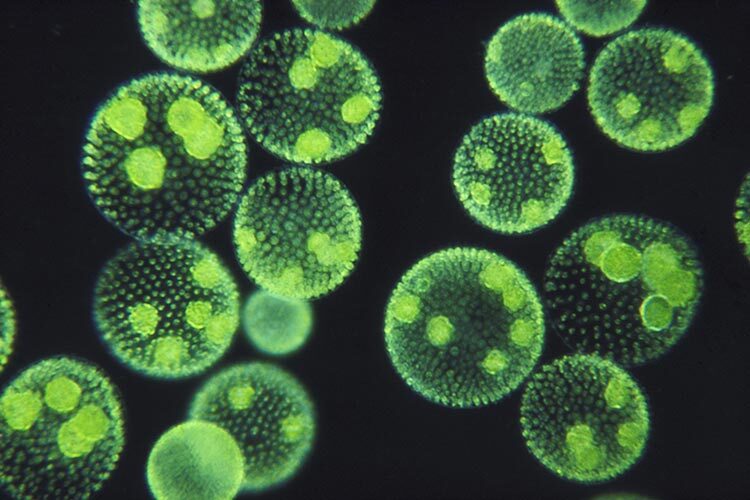

Among these microorganisms are microalgae, known for producing the biopolymers PHA and PHB, which are similar to polypropylene (a type of plastic used in packaging, clothing, and automotive parts). However, scaling up the production of these biomaterials using microorganisms faces limitations due to their specific biological requirements, such as nutrient control, the amount of CO2 in the environment, and even light intensity.

Microalgae and Carbon Dots

New strategies have emerged to enhance biopolymer production in microalgae systems. One such strategy involves controlling specific nutrients in the culture medium to induce “stress,” which activates a metabolic pathway for their production [4].

However, this “stress” can also significantly reduce cell growth, which is unfavorable. This has led to research focused on addressing this issue. For example, recent studies suggest that adding carbon nanomaterials, such as “carbon dots,” to systems under normal conditions can significantly increase the growth of these microorganisms [5-6].

Carbon dots are carbon nanoparticles ranging in size from 1 to 10 nanometers (nm) and possess unique properties such as fluorescence, biocompatibility, and low toxicity. They are highly versatile due to their ability to be combined with other compounds. Additionally, they can be obtained from organic materials like agricultural waste or common fruits.

These carbon dots are much smaller than cells and even smaller than most viruses, as 1 nm equals 0.000001 millimeters. Their tiny size gives them properties that are being investigated for their potential applications.

In this case, considering the current challenges and published references, an opportunity was identified to develop carbon nanoparticles that enhance the cell growth of microalgae under stress conditions, thereby increasing biopolymer production.

The microalgae selected for the study was Scenedesmus sp., known for its ability to accumulate biopolymers such as polyhydroxyalkanoates (PHA). Microorganisms produce these biopolymers as an energy and carbon reserve. Because this accumulation occurs under specific cultivation conditions, Scenedesmus sp. is considered a promising candidate for bioplastic production.

Carbon dots were created using prickly pears, fruits that require little water to grow and are rich in minerals and sugars, which provide the necessary carbon to create nanoparticles [7]. Additionally, the surface was treated with nitrogen, phosphorus, and a combination of both to enhance biocompatibility and optical properties [8].

Once prepared, these carbon dots were added to Scenedesmus sp. culture media of, and samples were taken every five days. The microalgae samples were analyzed to determine the concentration of carbohydrates, lipids, proteins, cell growth, and the amount of PHA present.

The study yielded positive results. The cell growth of the microalgae in cultures with carbon dots was superior to other methods, with an increase of 32% compared to the control [9,10].

Additionally, there was a 26.9% increase in PHA production, demonstrating that it is possible to enhance bioplastic production in microalgae cultures through the application of carbon nanomaterials derived from organic sources and sustainable methods.

Challenges to overcome

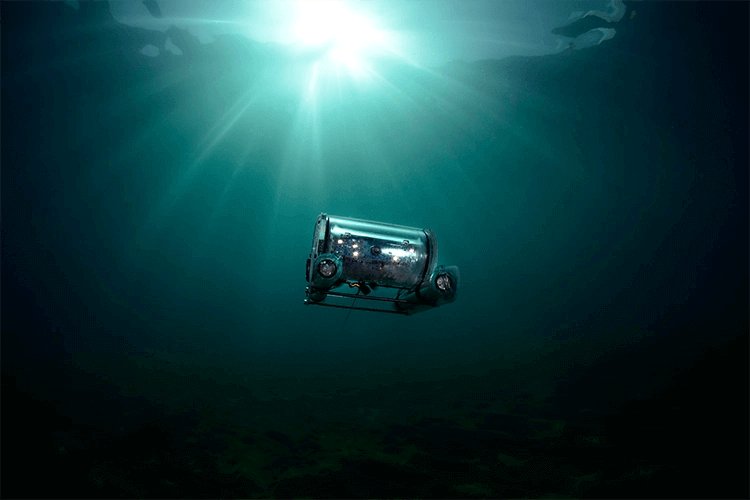

Despite its great potential, biopolymer production using microorganisms faces challenges for large-scale implementation, such as maintaining optimal growth conditions for microalgae in large volumes. However, the potential positive impacts of scaling up PHA and PHB production are considerable.

For example, the carbon equivalent emissions of polypropylene are 1.34 kg of CO2 per kg of the material. In comparison, a degradable biopolymer like PHA ranges from 0.032 to 0.49 kg of CO2 per kg of PHA [11,12,13]. Additionally, bioplastic production models can integrate CO2 capture systems, wastewater treatment, and the production of other compounds [3].

The conventional plastic market is projected to reach $56.36 billion by 2031 [14], making it crucial to conduct research that optimizes the growth and development of bioplastics, such as PHA and PHB, to meet the demand for biopolymers and have a positive environmental impact on the planet.

For more information:

Sánchez-Pineda, P.A., López-Pacheco, I.Y., Villalba-Rodríguez, A.M. et al. Enhancing the production of PHA in Scenedesmus sp. by the addition of green synthesized nitrogen, phosphorus, and nitrogen–phosphorus-doped carbon dots. Biotechnol Biofuels 17, 77 (2024).

References

- OECD, “Global plastic waste set to almost triple by 2060, says OECD,” Global plastic waste set to almost triple by 2060, says OECD. Accessed 25 Oct 2022.

- Schwarz AE, Ligthart TN, GoBizarro D, De Wild P, Vreugdenhil B, van Harmelen T. Plastic recycling in a circular economy; determining environmental performance through an LCA matrix model approach. Waste Manag. 2021;121:331–42.

- Atiwesh G, Mikhael A, Parrish CC, Banoub J, Le T-A T. Environmental impact of bioplastic use: A review. Heliyon. 2021.

- García G, Sosa-Hernández JE, Rodas-Zuluaga LI, Castillo-Zacarías C, Iqbal H, Parra-Saldívar R. Accumulation of PHA in the microalgae scenedesmus sp. under nutrient-deficient conditions. Polymers. 2020.

- Yang L, et al. Enhancing bioenergy production with carbon capture of microalgae by ultraviolet spectrum conversion via graphene oxide quantum dots. Chem Eng J. 2022.

- Zhao Z, Xue R, Fu L, Chen C, Ndayisenga F, Zhou D. Carbon dots enhance the recovery of microalgae bioresources from wastewater containing amoxicillin. Bioresource Technology. 2021;335:125258.

- Zenteno G, Juárez-Flores BI, Aguirre-Rivera JR, Ortiz-Pérez MD, Zamora-Pedraza C, Rendón-Huerta JA. Evaluación De Azúcares Y Fibra Soluble En El Jugo De Variantes De TunaS (Opuntia spp.). Agrociencia. 2015;49:141–52.

- Qie X, et al. High photoluminescence nitrogen, phosphorus co-doped carbon nanodots for assessment of microbial viability. Colloids Surf B Biointerfaces. 2020;191: 110987.

- Do Nascimento M, de los A dublan M, Ortiz-Marquez JCF, Curatti L. High lipid productivity of an Ankistrodesmus—Rhizobium artificial consortium. Bioresour Technol. 2013.

- Yang L, et al. Growth and lipid accumulation by different nutrients in the microalga Chlamydomonas reinhardtii. Biotechnol Biofuels. 2018;11(1):40.

- Alsabri A, Tahir F, Al-Ghamdi SG. Environmental impacts of polypropylene (PP) production and prospects of its recycling in the GCC region. Materials Today: Proceedings. 2022.

- Yu J, Chen L-X L. The Greenhouse Gas Emissions and Fossil Energy Requirement of Bioplastics from Cradle to Gate of a Biomass Refinery. Environmental Science & Technology. 2008;42(18):6961–6966.

- Mannina G, Mineo A. Polyhydroxyalkanoate production from fermentation of domestic sewage sludge monitoring greenhouse gas emissions: A pilot plant case study at the WRRF of Palermo University (Italy). Journal of Environmental Management. 2023;348:119423.

- SkyQuest Technology. Bioplastics Market Size, Share, Growth Analysis, By Raw Material (Sugar Cane, Potato, Corn Starch, Others), Product Type (Biodegradable (PBAT, PBS, PLA, PHA, Others), Non-Biodegradable (Bio-PE, Bio-PA, Bio-PET, PTT, PEF, Bio-PP, Others)), End-use Industry, and Region – Industry Forecast 2024-2031. Report ID: SQMIG15A2253. Global. June 2024.

.

Authors

Reyna Berenice González González: Ph.D. in Engineering Sciences. She is part of the Bioprocesses Unit at the Institute of Advanced Materials and Sustainable Manufacturing at Tecnológico de Monterrey, Monterrey Campus. Her research focuses on the synthesis, characterization, and application of carbon nanomaterials. To date, she has published over 46 articles in high-impact indexed journals, with more than 1,000 citations, an h-index of 19, and an i10-index of 27.

Pablo Alfredo Sánchez Pineda: Engineer in Nanotechnology and Project Specialist at the Bioprocesses Unit of the Institute of Advanced Materials and Sustainable Manufacturing at Tecnológico de Monterrey, Monterrey Campus. His research focuses on developing various carbon nanomaterials from green precursors, aiming to explore their potential application in biopolymers for food use. He specializes in the sustainable development of nanomaterials and their interactions in biological systems.