By Ángel Humberto Cabrera Ramírez, Marcela Gaytán Martínez, Aurea Karina Ramírez Jiménez, Iván Andres Luzardo Ocampo y Eduardo Morales Sánchez.

Popped sorghum and corn flours have demonstrated viscosity under different temperatures, making them ideal additives for products requiring thermal processing, such as soups and creams.

They can also improve the texture and stability of items like yogurt, pasta, and baked goods.

Unlike other starch modification methods, such as chemical treatments, popping is a quick (seconds-long) and non-toxic process that preserves the grain’s nutritional and bioactive qualities (protein, fiber, resistant starch, antioxidants, etc.), while enhancing its tech-functional properties.

Applying heat and causing structural transformations also improves other attributes, such as protein digestibility, and eliminates antinutritional compounds (which interfere with nutrient absorption and utilization).

This opens the door to a wide range of applications in the food industry, from creating healthier foods to developing products with innovative textures that appeal to consumers.

Flours from Popped Grains

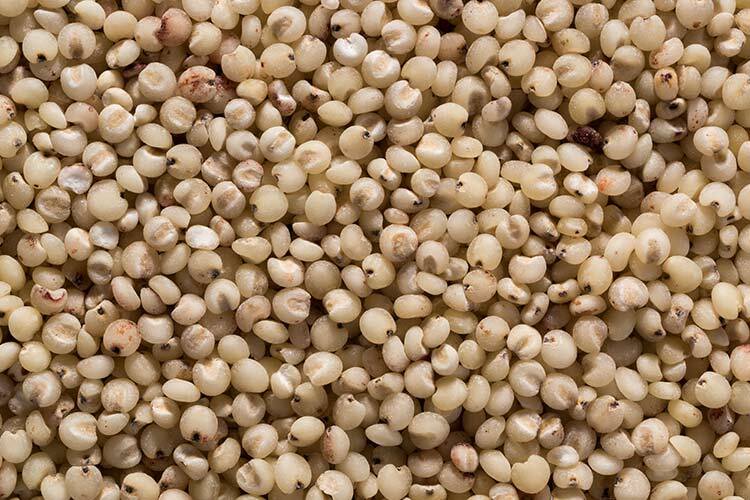

Popped grains, commonly known as “popcorn” when made from sorghum and corn, have traditionally been used as delicious and healthy snacks.

Flours made from these popped grains possess technological properties that make them novel ingredients for the food industry, helping improve the stability and consistency of many foods we consume.

The “CIATEJ-IPN-UAQ-Tecnológico de Monterrey” research group discovered that popping corn and sorghum grains produces flours with surprising technological properties.

These flours can enhance certain food characteristics, such as water absorption, solubility, and viscosity, that provide stabilizing and emulsifying effects. As a result, they could become key ingredients in improving the texture and stability of everyday products like yogurt, purées, and sauces.

How can such a simple process have such a big impact? The answer is that the popping process involves a thermal application that modifies the grain’s structure.

This process involves applying high temperatures (180 to 310 °C) for short periods (90 to 240 seconds), causing water vapor to increase inside the grain. This builds pressure that bursts the outer layer (pericarp) and rapidly expands the grain.

This structural change affects texture and alters the grain’s “physicochemical” and “rheological” properties.

Transforming Starch

To understand how this relatively simple process has significant implications for grain properties, we must focus on its main component—starch. Starch makes up about 60% of the grain’s total weight and is one of the primary energy-storage carbohydrates in plants.

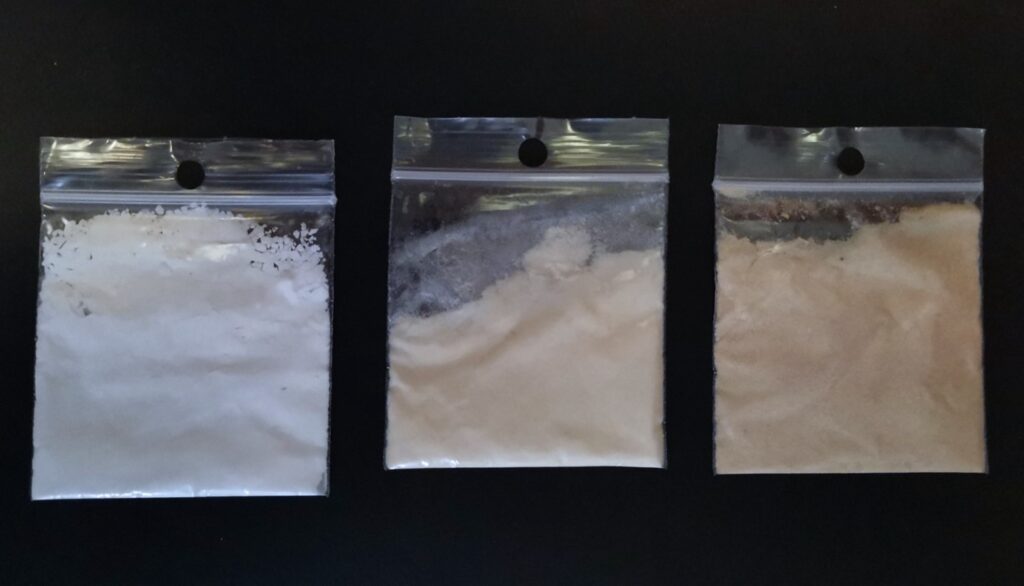

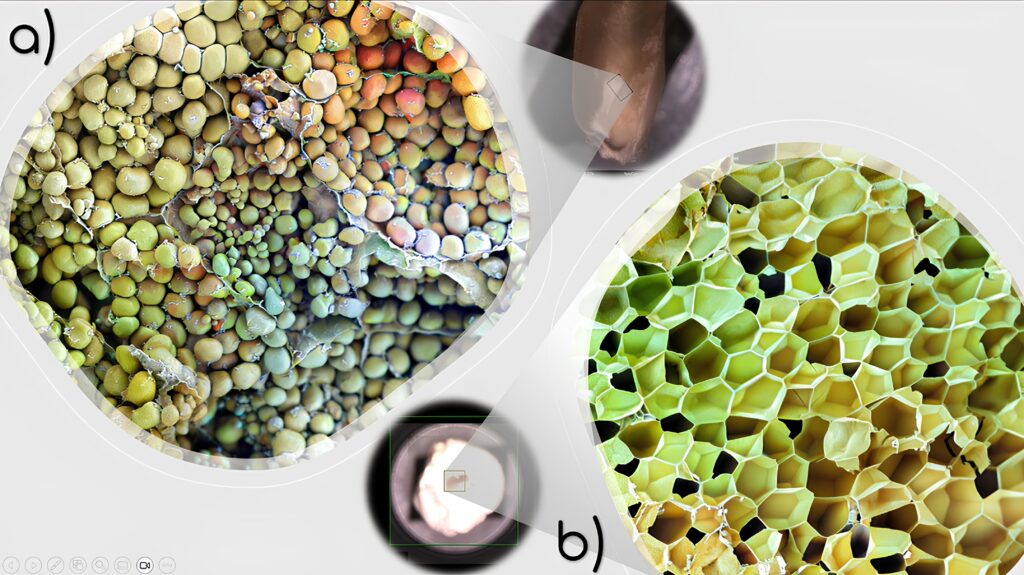

During the popping process, the starch undergoes dry gelatinization. It breaks apart, rearranges, and forms new bonds. This results in a physical transformation, turning the starch from a semi-spherical shape (Figure 3a) into a porous, honeycomb-like structure (Figure 3b).

This physical change gives popped grain flours a greater ability to absorb and interact with water and oil, as both can fill the newly formed “holes.” This, in turn, affects their ability to act as stabilizers in various food products.

In this context, “stabilizers” help bind other ingredients together or provide structural support to prevent them from separating.

Flours from popped grains represent a promising area of innovation in the food industry, particularly in unconventional grains like sorghum.

Their ability to enhance consistency, stability, and texture makes them valuable ingredients in processed food formulations. With further research, these flours could revolutionize large-scale food production and development.

References

- Cabrera-Ramírez, A. H., Castro-Campos, F. G., Gaytán-Martínez, M., & Morales-Sánchez, E. (2020). Relationship between the corneous and floury endosperm content and the popped sorghum quality. Journal of Cereal Science, 95(March), 102999.

- Cabrera-Ramírez, A. H., Gaytán-Martínez, M., Gonzáles-Jasso, E., Ramírez-Jiménez, A. K., Velázquez, G., Villamiel, M., & Morales-Sánchez, E. (2023). Flours from popped grains: Physicochemical, thermal, rheological, and techno-functional properties. Food Hydrocolloids, 135(August 2022), 108129.

- Cabrera-Ramírez, A. H., Morales-Sánchez, E., Méndez-Montealvo, G., Velazquez, G., Rodríguez-García, M. E., Villamiel, M., & Gaytán-Martínez, M. (2021). Structural changes in popped sorghum starch and their impact on the rheological behavior. International Journal of Biological Macromolecules, 186(July), 686–694.

- Castro-Campos, F. G., Cabrera-Ramírez, A. H., Morales-Sánchez, E., Rodríguez-García, M. E., Villamiel, M., Ramos-López, M., & Gaytán-Martínez, M. (2021). Impact of the popping process on the structural and thermal properties of sorghum grains (Sorghum bicolor L. Moench). Food Chemistry, 348, 129092.

Authors

Ángel Humberto Cabrera Ramírez. Principal Researcher at the Center for Research and Assistance in Technology and Design of the State of Jalisco (CIATEJ), Southeast Subsidiary (Mérida, Yucatán). His research focuses on food processing and its impact on major components (such as carbohydrates and proteins), as well as its bioactive compounds; the study of physicochemical, structural, rheological, and techno-functional properties of native and modified biopolymers; and the extraction of functional ingredients from agro-industrial by-products.

Marcela Gaytán Martínez. Research Professor in the Food Science and Technology at the Faculty of Chemistry Graduate Program (Autonomous University of Querétaro). Her research lines include the use of emerging technologies for the development and study of carbohydrates derived from cereals, legumes, and agro-industrial by-products to address national problems related to the nutrition of Mexicans.

Aurea Karina Ramírez Jiménez. Professor and leader of the “Sustainable Bioproducts” group. Her research is directed at the nutrigenomics of functional foods focused on agro-industrial waste, mainly bagasse, agave vinasses, and other food industry by-products.

Iván Andres Luzardo Ocampo. Professor-Researcher at the Institute for Obesity Research and the Department of Bioengineering at Tecnológico de Monterrey, Guadalajara Campus. His main research lines include the impact of food matrices on disease models (obesity, inflammation, and cancer), the impact of food processing technologies, and gastrointestinal simulation models.

Eduardo Morales Sánchez. He holds a Bachelor’s degree in Electronics from B.U.A. of Puebla, a Master’s in Instrumentation from the Autonomous University of Querétaro, and a PhD in Materials Engineering from the same university. His research areas are food technology, industrial processes, and bioelectronics. He is a Level III National System of Researchers (SIN). In 2013, he received the IPN “Technological Development” Research Award. He has published 152 scientific articles and holds 15 national and international patents. He is a full-time National Polytechnic Institute (IPN) professor assigned to CICATA, Querétaro Unit.