A team of researchers from Tecnológico de Monterrey has devised a solution to tackle water scarcity: a project that uses solar energy to desalinate seawater.

Although 70% of the Earth’s surface is covered by water, around 3.7 billion people worldwide – nearly half of the global population – are affected by a lack of access to clean water. According to the 2024 United Nations World Water Development Report, this number could rise to 5.7 billion by 2050.

Desalination involves removing salt and minerals from seawater through methods like reverse osmosis. However, this process requires vast amounts of space and energy, often from fossil fuels, making it both expensive and environmentally unsustainable.

Carlos Rivera, a researcher at the Institute of Advanced Materials for Sustainable Manufacturing and a professor at the School of Engineering and Sciences at Tecnológico de Monterrey, explains that the method they developed combines two existing technologies: solar thermal collectors and membrane distillation.

“It’s a sustainable process that doesn’t pollute. We ran dynamic simulations, and now we want to build a prototype to prove that seawater can be desalinated using solar energy,” says Rivera.

How Does a Sustainable Desalination System Work?

Recently, researchers from Tecnológico de Monterrey, in collaboration with colleagues from Imperial College London, developed a hybrid collector that, much like a solar water heater, harnesses solar radiation to heat liquids and can generate energy.

This device uses a parabolic mirror to focus solar radiation onto a triangular duct. The duct walls are equipped with photovoltaic cells, similar to those found in solar panels, through which fluids such as water or gas flow commonly used in industrial processes.

The cells collect the solar rays and turn them into electrical energy, but in the process, they heat up, which can affect their performance. Water is also used to cool them, but in turn, their temperature rises to evaporation levels.

When the scientists noticed the water evaporating, they realized they could combine this system with a vacuum membrane distillation process.

In this method, water vapor passes through a porous layer about the size of a sheet of paper made from a polymer similar to the Teflon tape used in plumbing but four times thinner.

“Only vapor can pass through that membrane, and to make that happen, we need to heat the water to temperatures between 50 and 80 degrees Celsius. It’s like when you heat water on the stove, and steam starts to rise as the temperature increases; in this distillation, we separate the vapor without reaching the boiling point,” explains Rivera.

In the end, the vapor generated can be drawn in by a vacuum pump into a container where it can condense—that is, it cools back down and returns to its liquid state.

Additionally, the electrical energy generated by the photovoltaic cells can power the system’s mechanisms to track the sun and capture as much solar radiation as possible, as well as the pumps that circulate the fluid and various types of sensors.

The researcher notes that another advantage is that the system can be designed to be compact. This means a smaller membrane area can produce more water than traditional distillation processes, which require large-scale installations.

Producing 1,000 Liters of Water Per Day in an Area of 12 Square Meters

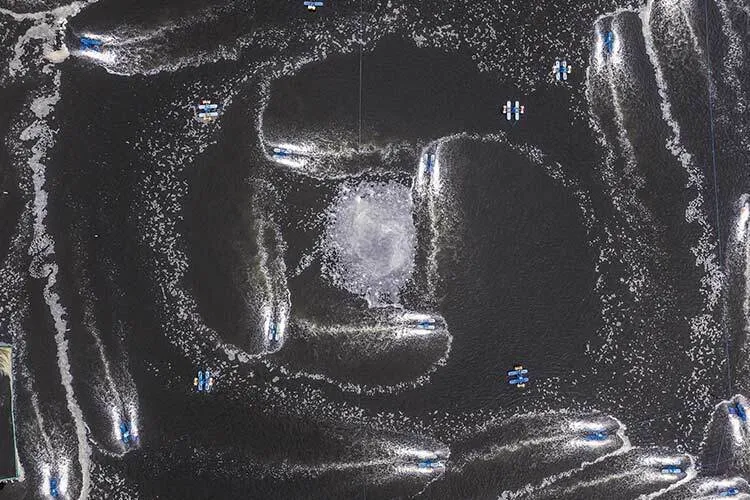

The team of researchers from Tecnológico de Monterrey conducted tests in areas with abundant solar resources in collaboration with scientists from Nanyang Technological University (NTU), Singapore.

For example, they conducted their experiments in coastal locations like La Paz and Acapulco in Mexico, Nadi in Fiji, and Singapore. However, the tests can also be applied to desert or semi-arid regions, such as Sonora or Sinaloa, where wells commonly extract water containing salts and other minerals.

The results showed that four solar concentrators with membrane distillation, each approximately three meters long by one meter wide —that is, 250 liters per collector— can produce about 1,000 liters of water per day.

The United Nations General Assembly recognizes the right of all human beings to access a sufficient amount of water for domestic and personal use (between 50 and 100 liters per person per day), which must be safe, acceptable, and affordable— meaning the cost should not exceed 3% of a household’s income.

“We are developing the prototype for vacuum membrane distillation and conducting experimental tests at the lab level. The next step is to integrate the two technologies into a single prototype. The goal is to have a fully functioning one within two years so that companies can see that it’s economically feasible and scalable,” says Rivera.

Looking ahead, the researcher envisions this project as a sustainable, lower-cost alternative for providing water for human consumption and other uses to communities or developing countries.

Did you find this story interesting? Would you like to publish it? Contact our content editor to learn more at marianaleonm@tec.mx