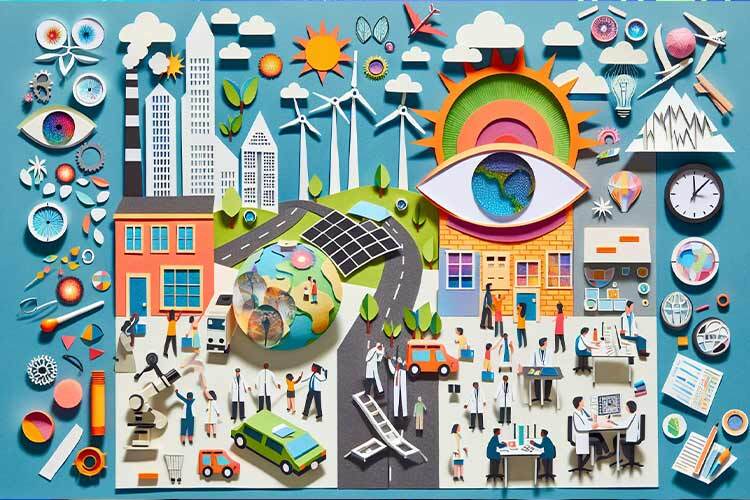

The circular economy proposes redesigning products, plastics in this case. This means that this waste will be reused, repaired, re-manufactured, or will simply have better performance in the future.

Some automotive industry polymers are irreplaceable, such as polyvinyl butyral (PVB), a type of plastic that is used as a “sandwich” in car windshields, to prevent them from shattering when they break.

They are discarded at the end of their useful life, but researcher Andrea Guevara Morales, co-leader of the Advanced Manufacturing research group at the Tec de Monterrey School of Engineering and Sciences, and her work group have found that if PVB is mixed with other polymers, they can obtain a solid lubricant, which has various engineering applications.

Transforming plastic into solid lubricant

Single-use plastic doesn’t provide benefits and often can’t be integrated into the circular economy, but there are other plastics that are widely used in engineering that may have a second chance.

Andrea Guevara Morales explains that her research group at the Laboratory for Fracto-Mechanical Testing of Engineering Plastics, located on the State of Mexico Campus, intends to “find a use for this material when it’s discarded so that it doesn’t end up in a landfill.”

Each vehicle contains up to one kilogram of PVB. Graduate students from the group have mixed this material with other polymers, such as polyamides (or nylon) and acetal, and have observed that the friction and wear rate of these substances decreases due to PVB’s good adhesion and low shear strength.

These characteristics mean it could be used as a solid lubricant to reduce friction between surfaces that slide over each other, without the need for a liquid medium.

“In laboratory wear tests, we’ve found that the friction coefficient decreases significantly, exhibiting behavior similar to that of known lubricants such as Teflon”.

Morales, who holds a master’s degree and a doctorate in mechanical engineering from Imperial College, believes that these tests are still in their initial stages and that more needs to be done to define which conditions are required for it to work.

It is also necessary to do further analysis at the end of this solid lubricant’s life cycle, in order to find other ways of using it and avoid turning the current problem into a future one.

This project has received funding from the State of Mexico government, via the State of Mexico Council for Science and Technology.

Circular materials: other projects

The plastics laboratory is developing projects that follow three main lines of research: fast fracturing in engineering plastics, tribology, and new materials which contribute to a circular economy.

For instance, they are researching the characteristics of engineering plastic materials under impact or high-speed load conditions. Such polymers can have a 60-year life cycle and perform well, but they can also crack.

Andrea Guevara Morales provides the example of polyethylene pipes, which are used to transport natural gas and water. The laboratory is studying the phenomenon of fast fracturing, which has a high potential for causing destruction, given that cracks can spread at 300 meters per second.

As a crack can form at that speed during installation or excavation and cause a fracture, her group is focusing on the two areas in the plastic material where cracks occur, in order to prevent them.

They are seeking to prevent this kind of failure by examining the characteristics of the plastic material using different techniques, under both plane stress and plane strain conditions.

The expert is part of a group that is advising the Mexican standards committee to propose a new Mexican standard for regulating fast fracturing and achieving a wider understanding of the phenomenon.

They have submitted a preliminary project which has already been approved by a subcommittee. However, it has to be reviewed by several groups and final approval will surely take some time.

Other lines of research to do with circular materials at the State of Mexico Campus include: nanostructured materials, additive manufacturing, synthesis and characterization of hybrid organic-inorganic materials, surface engineering, and modeling physical-chemical phenomena.