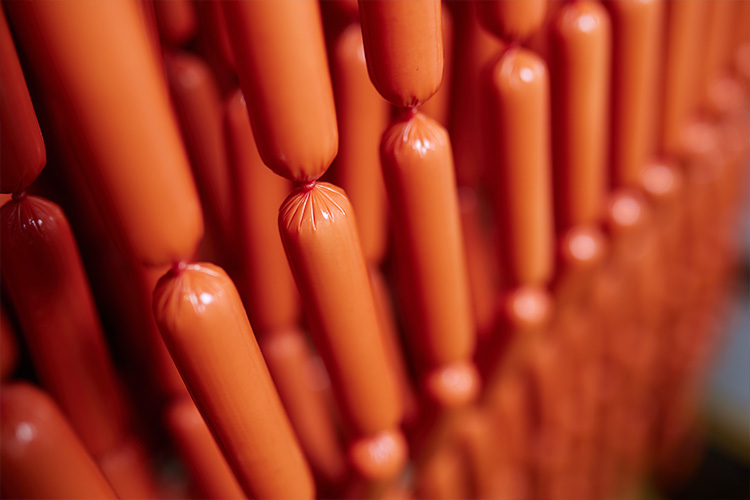

Can you imagine your hot dog being healthier and more nutritious? A team of researchers has replaced chemical additives with natural ingredients to transform and improve the product’s qualities.

Julián de la Rosa Millán, a researcher at the School of Engineering and Sciences (EIC) and a member of the Food Security research group at Tec de Monterrey, says the study focused on using mustard flour as an organic ingredient in the production of Vienna-style sausages—a food that’s very popular among adults, teens, and children in both Mexico and the United States.

“When we eat processed meats, we’re also consuming additives that are necessary for the sausage or ham to look and behave the way we expect them to,” says De la Rosa. “These are mainly from the nitrite, nitrate, and phosphate groups—compounds needed to achieve color, moisture retention, and texture.”

Although these additives are present in very small amounts in processed meats—yet have a powerful effect—some, such as phosphate salts, have been linked to negative health effects when products containing them are consumed frequently and over the long term.

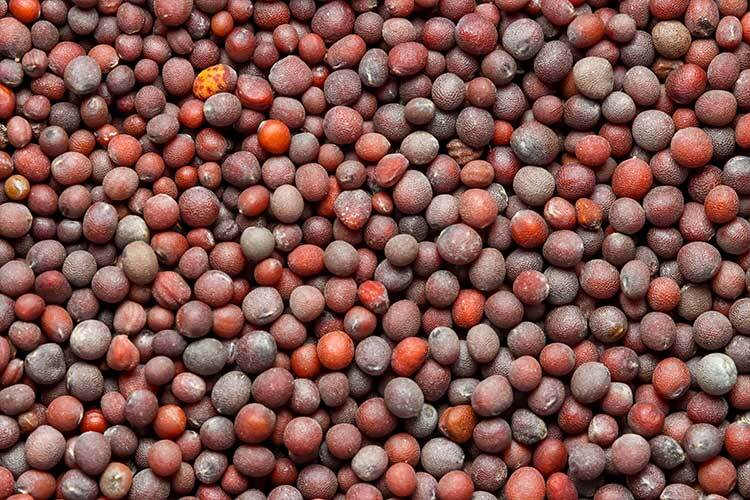

The idea emerged from a collaboration with the company Food Sinergy Sapore and the Canadian brand GS Dunn, which produces goods made from mustard seeds. Together, they evaluated the use of two types of protein-rich flour—a byproduct of oil production—as an alternative to phosphates and as a way to reduce other chemical ingredients like nitrites.

At the end of the study, the team produced a technical report that included results such as yield, sensory testing, and antimicrobial capacity. This report was delivered to GS Dunn to help promote mustard flour as a functional ingredient in the meat industry based on solid data. In addition, the team—made up of researchers and students—published the project’s findings in the International Journal of Food Science + Technology, an open-access scientific journal.

Healthier sausages with mustard flour, in collaboration with the industry

In sausages, sodium phosphate is used to retain water between muscle fibers or within the meat mixture during storage and up until cooking.

Maintaining moisture is key to achieving a juicy, appealing texture. Meanwhile, sodium nitrites and nitrates help preserve the sausages’ pink color and prevent bacterial growth. However, both are chemical compounds used as additives that—in excess—can raise blood pressure and cause kidney damage, among other health issues.

For this reason, countries like Canada are pushing for regulations to reduce phosphate content in meat products and other foods.

This presents a real need for producers in those countries to find functional substitutes, and provides researchers with an opportunity to explore the use of flours derived from mustard oil extraction byproducts. Sausages were chosen for this project because they’re a widely consumed and affordable food, making them ideal for evaluating the potential of these flours as functional ingredients.

The Canadian company provided the two types of flours, which were labeled with internal codes, explains De la Rosa. “One still had a notable spicy kick, with a bit more oil, and the other had a more neutral flavor.” This allowed the team to develop different formulations and compare whether the oil content and spiciness had any impact on the sausages’ sensory and functional properties.

The production process itself wasn’t changed—they used industrial mixers where the mustard flour was incorporated at the same stages as the chemical additives. In the formulations developed for the study, phosphates—typically making up to 0.5% of the total product—were eliminated, and the use of nitrates and nitrites was cut in half (they’re normally used at up to 156 milligrams per kilo of sausage) without significantly affecting the sausages’ flavor, color, or texture.

Sausages with more protein and fiber

Functional ingredients are those that not only serve a technological purpose in a food’s properties but also provide added health benefits for consumers.

One of the main reasons mustard flour was studied as a substitute for chemical additives in sausages was its high protein content—around 40%—which not only boosts nutritional value but also helps retain moisture and improve texture.

By using the two types of mustard flour, the researchers were able to increase the sausages’ protein content from 17.92% to 19.36%. On top of that, the flour added dietary fiber to the new formulation—a key difference from conventional sausages, which typically contain no fiber at all.

The mustard flour formulation also resulted in sausages with improved texture—more elastic, firm, and chewable—over the 21-day storage period used in the study. “Protein works like an emulsifier,” explains De la Rosa, “meaning it helps the meat, fat, and water bind properly so the product stays stable.”

In tests of elasticity and firmness, the sausages didn’t break when bent or twisted—a standard indicator of high meat quality and low use of starches or fillers in these kinds of products.

Another benefit was that the mustard flour helped keep bacterial levels low, including Staphylococcus aureus and certain fungi—even outperforming phosphate salts—thanks to its content of glucosinolates, compounds known for their antioxidant and antimicrobial properties. During refrigerated storage, the researchers observed no bacterial growth;, even when bacteria were intentionally introduced, they were eliminated.

The organic ingredient also helped increase production yield, with a 4% boost in final volume and weight, without changing the amount of other raw materials. That means in a one-ton batch, producers could get up to 40 additional kilograms of sausage.

Encouraged by the lab results, the researchers brought 20 kilograms of sausage to a specialized meat product fair, where they cooked and presented the samples to industry experts for a controlled sensory evaluation. The response was overwhelmingly positive—only the most experienced tasters could detect a difference between the two flour formulations, due to the variation in spiciness from mustard essential oils.

A sustainable alternative with public health benefits

Since mustard flour is derived from a byproduct that would usually be discarded, turning it into a functional food ingredient represents an efficient use of resources with potential economic and environmental benefits.

Repurposing it helps reduce waste and makes better use of plant-based resources.

Beyond its commercial applications, this technology could also help improve public health by adding fiber and protein to affordable, everyday foods.

“For example, this could be especially beneficial for vulnerable populations,” says De la Rosa. “It’s a double effect: we’re removing an ingredient that could have negative metabolic effects, and we’re providing high-quality protein.”

One of the next steps in this line of research will be to investigate how the ingredient affects the glycemic index, exploring its potential use in foods for individuals with diabetes. Researchers also plan to explore introducing it to the baking industry as a replacement for chemical additives, aiming to reduce the need for preservatives and develop products with improved texture and nutritional value.

Were you interested in this story? Do you want to publish it? Contact our content editor to learn more marianaleonm@tec.mx