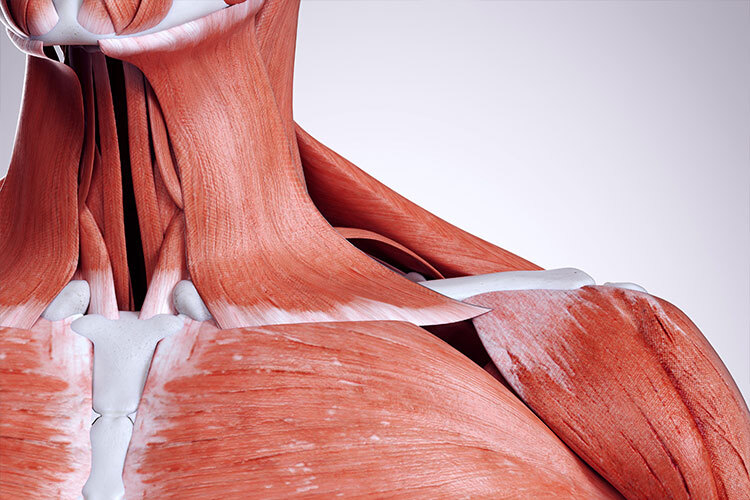

In tissue engineering, one of the biggest challenges is ensuring that 3D-printed materials maintain their structure over long periods. A group of researchers has proposed a technique that combines multiple materials to overcome this barrier.

In this interdisciplinary field, engineering, biology, and medicine are combined to restore, maintain, and improve damaged tissues or organs, as well as to print cultured meat or shape plant-based meats.

To achieve this, cells, biocompatible materials and molecules are used, either in the laboratory, in a petri dish or a bioreactor, or directly in the body.

Although the field has advanced significantly in recent years, it remains difficult to create thick structures with internal channels that allow tissue to vascularize—to develop blood vessels—keep cells alive for weeks or months, and prevent them from degrading or losing their shape. These obstacles have limited the printing of more complex structures, such as muscle.

“In the case of cultured meat, we could cultivate filaments with cells so that they would grow and form tissue, but after seven days they would fall apart,” says Grissel Trujillo, a research professor at the School of Engineering and Sciences (EIC) of Tec de Monterrey.

To solve this, Trujillo, Mario Álvarez, research professor at EIC, along with a multidisciplinary and multi-institutional group, including researchers from the University of Engineering and Technology of Lima, Peru, and the Massachusetts Institute of Technology (MIT), United States, demonstrated in a recent article the use of multi-material chaotic printing.

It can be used to print bands of different materials, allowing for the printing of more complex tissues that are resistant and firm.

Chaotic Printing with More Than one Material

The technology they propose is an evolution of chaotic printing, which Trujillo and Álvarez developed a decade ago.

“I don’t know if you remember the toothpastes you used to extrude that had white and green bands,” says Álvarez. “Imagine we do that, but instead of just having two types of banding, we can have bands of up to eight different materials.”

The new method uses a print head with static mixers that generates complex patterns within the printed filaments. The key lies in combining three main components: a bio-dye embedded in gelatin, a material to form internal channels, and a structural reinforcement layer made of alginate.

Of the materials, one can provide support, another can make holes to allow vascularization, and two others can have different types of cells, for example.

“That gives you a very complete system; you can make practically any tissue,” says Álvarez.

The advantage of this approach is that it allows for the production of structures with internal channels and robust walls. The pre-vascularized channels enable the transport of oxygen, nutrients, and waste products, replicating the functions of a natural vascular system.

The reinforced layers ensure that the filaments can withstand prolonged cultivation of up to 21 days, an important advance for the growth of complex tissues such as skeletal muscle.

“In the article, we demonstrated that we can extend its lifespan by more than 20 days, but we can actually prolong it further,” says Trujillo. “It’s important to extend the culture time because it gives the cells a chance to grow and communicate.”

Impact and Applications of Prevascularized Hydrogels for Regenerative Medicine

These results represent an advance in advanced biofabrication, demonstrating that it is possible to design hydrogels that not only remain viable for extended periods but also promote the alignment and proliferation of myoblastic cells, immature white blood cells that form in the bone marrow.

These types of structures are fundamental for developing functional tissues that can be used in regenerative medicine, meat printing, disease models, or drug trials.

“Our hope as a research group is that it becomes a technological platform that other researchers can use for different purposes,” says Trujillo.

In their own research, they seek to apply the technology to develop muscle in cultured meat, which in the future would allow the development not only of ground meat, but also steaks and other types of cuts.

Beyond muscle, the strategy can be adapted to manufacture other tissues, including cartilage, cardiac tissue, or even tumor models with integrated vasculature, making it a promising tool for both research and future clinical applications.

Their research represents such progress in this type of technology that it earned the team the cover in Biomaterials Science, a prestigious scientific journal in the field of biomaterials science and engineering.

“The cover is a photo of one of our students holding one of these print heads in her fingers, and you can see the different materials entering the tip,” says Álvarez.

With their research, the experts mark a key step that brings the scientific community closer to real and affordable solutions for regenerative medicine, meat printing, and the manufacture of complex organs and tissues.

Did you find this story interesting? Would you like to publish it? Contact our content editor to learn more: marianaleonm@tec.mx