Mariel Alfaro and Ulises Dávila grew attached to a little dog that had narrowly escaped death. “At the vet I go to, the doctor rescues a lot of dogs. He has one that was hit by a car and had to have its back legs amputated. Even though the surgery saved its life, I could see its quality of life wasn’t very good,” Mariel recalls.

That experience sparked the idea to create ProForm Dynamic, a startup the two co-founded as researchers at the School of Engineering and Sciences on the Mexico City campus. Their goal is to provide animals with access to affordable, custom-made prosthetics using technologies like 3D printing, artificial intelligence, and biocompatible materials.

Mariel is a biomedical engineer, and David is a bionic engineer, and both are animal lovers.

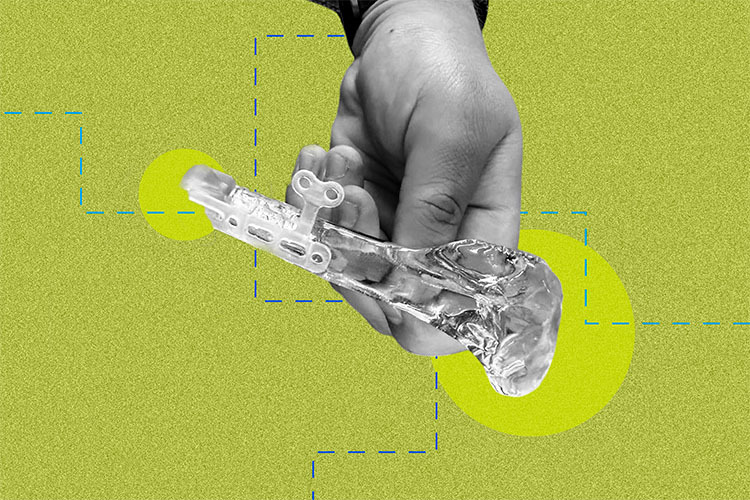

The science and technology-based company they launched became a way to put their expertise to good use. Dávila has focused on the development of orthotic devices and has worked with hospitals on research and development of bone fixation systems, which use plates and screws to stabilize bones.

“I’m very protective of my dogs. One of them is now a senior and, because of her age, is starting to develop joint deformities. She has to wear elbow braces and other types of orthopedic gear,” says Alfaro, who is also a researcher at the Institute of Advanced Materials for Sustainable Manufacturing.

Ergonomic, Comfortable, and Lower-Cost Prosthetics

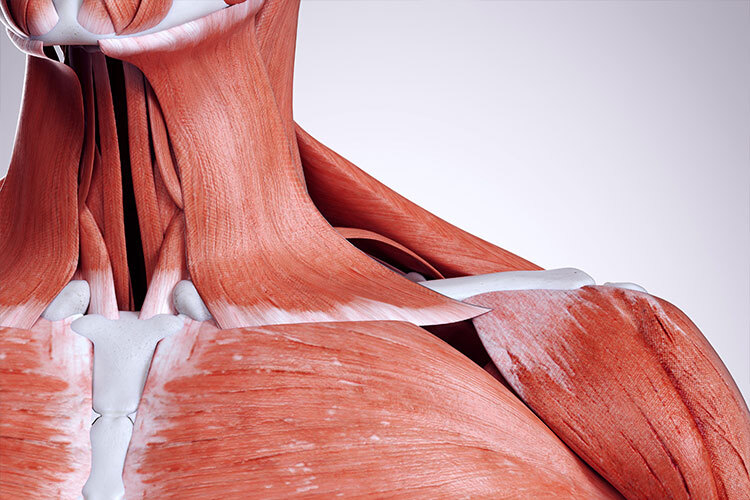

In Mexico, there are very few materials or tools specifically designed for animal prosthetics. While some can be adapted by veterinarians, they often don’t align with the animal’s anatomy and can result in unwanted side effects.

“The idea behind this business is to make it feasible not only for the animals that need it, but also for their owners, who, for example, often can’t afford to pay 90,000 Mexican pesos just for a hip replacement prosthesis, not to mention the surgeon’s and anesthesiologist’s fees for the procedure,” explains Dávila.

In the case of the dog that inspired them, the researchers worked with the vet to develop an implantable prosthetic proposal. To fit it, they placed a socket directly onto the bone, which prevents the remaining bone fragment in the stump from continuing to fracture and lose density, and allows for a prosthesis to be attached.

The researchers estimate that the final cost to users could be reduced by up to 50% compared to current foreign alternatives, which are typically mass-produced—meaning they’re not tailored to individual animals—and come with added expenses like tariffs and import fees.

As for the potential market, Alfaro points out that they are focusing on a generational gap of pet owners between the ages of 21 and 40. According to INEGI, there are 80 million pets in the country, and in cities like Monterrey, Guadalajara, and Mexico City, many adults are opting for companion animals over having children.

From-Scratch Design of High-Precision Plates and Prosthetics

The technology developed for ProForm Dynamic blends artificial intelligence with advanced design and manufacturing to create devices tailored to the specific anatomy of each animal.

The fabrication process begins with a CT scan, followed by the use of AI algorithms to produce a 3D reconstruction of the bone and achieve a precise segmentation of fractures in the affected area.

Using this data, the team designs—from the ground up—plates, prosthetics, or orthotic devices that fit with high precision to the actual shape of the bone or limb.

Once the design is validated, prototypes are produced using 3D printing with biocompatible resins approved by the U.S. Food and Drug Administration (FDA), allowing veterinarians to rehearse the procedure before the final surgery. For the final product, they use medical-grade materials such as ELI-grade titanium—the same type used in human bone fixation plates—or certified resins.

The company is also certified under Mexico’s Official Standard NOM 241, which governs best practices in the development of medical devices.

The Path Toward Artificial Exoskeletons

Throughout the process, there is clinical collaboration, says Dávila. The team works closely with the veterinarian performing the procedure to fine-tune the design and materials.

After surgery, there’s a postoperative follow-up to ensure the animal responds well to the device or to determine if adjustments are needed.

The company is also focused on designing tools and devices like exoskeletons that can capture biomedical data to help evaluate and improve an animal’s rehabilitation.

Alfaro shares that they actually hold a patent for an active lower-limb orthosis for humans—an exoskeleton, similar to Iron Man’s armor, designed for the leg. The device learns how a person walks and, based on their range of motion, activates motors to assist with mobility and help support their weight, making recovery easier.

“This kind of technology can cross over into both fields. The patent was registered for a human lower limb, but that doesn’t mean it can’t be applied to a dog or a racehorse.”

Scalable Technology for Humans

The team is currently focused on developing implants and their first prosthetics for small species, primarily dogs and cats. Eventually, they aim to expand into manufacturing orthotic devices and serving a market that includes larger animals like horses.

Looking ahead, the researchers hope to adapt their technology for human use as well, despite the lengthy validation process that entails.

Today, the company handles custom-made prosthetic cases on demand from two locations: an office in Monterrey and a production facility in the State of Mexico equipped with Computer Numerical Control (CNC) machinery and FDA-certified medical-grade 3D printers.

Alfaro notes that they are currently working closely with the EBCTec innovation ecosystem to secure investment and meet the company’s goals, including becoming the national leader in prosthetics and orthotics for small species. Their business model also envisions future operations in regions across Latin America, the United States, and Canada.

“This project is about improving animals’ quality of life. We know our pets won’t be with us forever, but while they are, they deserve the same care we’d want for any of our family members or loved ones. We aim to be an option for pet owners seeking solutions that truly make a positive difference in their lives,” Dávila concludes.

Did you find this story interesting? Would you like to publish it? Contact our content editor to learn more: marianaleonm@tec.mx.