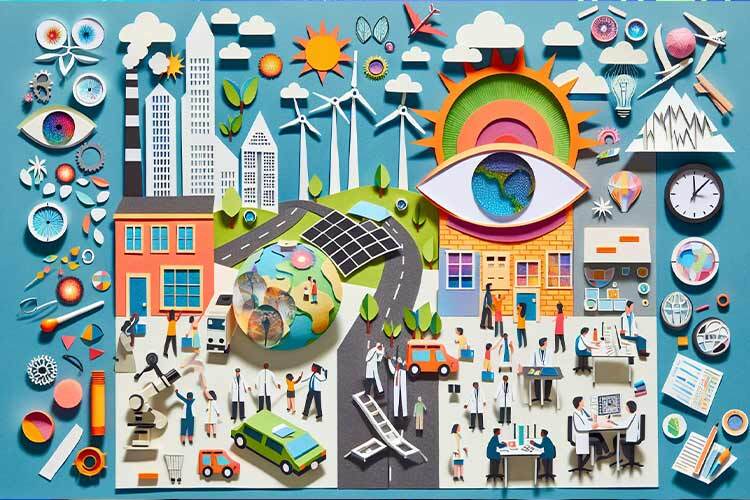

From reducing livestock’s methane emissions to improving irrigation methods and effectively using fertilizers, the Tec de Monterrey’s Experimental AGRO Field (CAETEC), located at KM 188 on the Mexico-Querétaro highway, is consolidating as a large laboratory.

The agricultural activities, size, conditions, and multidisciplinary talent that converge here, make it a perfect place to implement various projects for the private industry.

“This experimental agricultural field is considered the largest laboratory Tec de Monterrey system has. We affectionately call it a ‘ranch,’ but it is a large area with industry interconnections,” Arturo González de Cosío, director of CAETEC, says in an interview with TecScience. “What we are looking for is to generate data and manipulate that information to better understand how to change agriculture positively”.

We will tell you about some of the largest and most innovative projects in this vast “data farm” part of the Querétaro Campus, to take advantage of the information and produce more sustainably.

A Data Farm at the Service of Academia and Industry

At first glance, CAETEC looks like a small 70-hectare ranch, but actually, it is a data farm. In the middle of the barley crops that sway in the wind, Juan Valiente, a research professor in emerging food technologies and nutraceuticals, and a student obtain metrics of the barley to analyze its growth.

Ahead, drip irrigation operates in greenhouses that contain dozens of varieties of peppers and tomatoes and is controlled in all aspects by José Antonio Ramírez, an agricultural specialist.

“At first, the ‘ranch’ was the place where students of the Biosystems Agro-food Engineering career performed their professional internships, but now, one could almost say that all agricultural production is a pretext for collecting data on what happens in the open field, greenhouses, and the stable”, explains González de Cosío.

By interconnecting the machinery, specific and cross-referenced information is obtained, allowing them to offer the data to academia and the industry that desire to develop innovations.

Researchers from different Schools and Institutes of the Tec converge at CATEC to carry out projects in any of its four areas. This is the case of David Balderas, a research professor in the unit of enabling systems for sustainable manufacturing at the Institute of Advanced Materials for Sustainable Manufacturing (IAMSM), who is developing two image detection systems for greenhouses.

The first is aimed at identifying humidity, CO2 and particles, and the second at detecting diseases and pests.

“The goal is for this device to navigate inside the greenhouse an identify temperature changes in the plant; thus, viruses or a lack of water could be detected”, he explains.

Precision Agriculture

The agricultural sector inside the ranch has three main areas: protected agriculture, including greenhouses; extensive agriculture, focusing on grains and forages; and fruit farming, particularly vineyards.

Technologies employed include GPS devices installed on tractors, akin to those used in aircraft, as well as soil sensors, drones, satellites, and software for data processing. For instance, a tractor equipped with GPS can communicate with a seeding machine through a sensor to determine if fertilizer application is necessary. Such sensor, SoilX, analyzes soil at four levels based on its physical and chemical characteristics.

“A tractor is no longer just a power machine; it’s a precision machine. This precision is built through data and information,” comments González de Cosío, who also mentions that CAETEC will liaise with tractor company John Deere, which plans to invest at least four million dollars in establishing a training center.

Both within and outside the greenhouse, CAETEC employs an artificial intelligence system called IIVO by Hoogendoorn. This system collects climate data and, through analysis, determines the optimal time for irrigation or fertilizer application, thereby optimizing water usage.

The Future of Milk: Methane Emission Reduction

In the barn, where CAETEC began 47 years ago, 160 cows enjoy the world’s most innovative milking technology.

Guadalupe López, a livestock specialist, explains that besides meticulously recording the liters of milk each cow produces and the fat level of the liquid, the animals have many benefits.

“Here is like a five-star hotel for them. They sunbathe, rest, and eat whenever they want, and when they need to, they go to the milking line where Laval robot arms attach suction cups for milk extraction”.

CAETEC is equipped with three out of five of these groundbreaking robots located in Mexico. Although adapting to this new milking method took about three years, the fact that cows live stress-free has resulted in increased production, and more importantly, everything is measurable.

This, along with being a closed farm producing its fodder, is why Nestlé chose CAETEC to develop a strategic global project to find actions that help reduce methane emissions produced by cow manure. Research lines will evaluate feeding, genetics, gastrointestinal processes, and cow feeding schedules to define best practices.

Nearly 50 years after its beginning, CAETEC is recognized as a laboratory where innovative solutions are developed, taking in consideration the environment, animal welfare, and human health.

“If I take care of a single maize seed, I can have hundreds of maize seeds; it’s a multiplier effect. We generate value. And that value resides not only in the maize grain or seed itself but in all the products and services it will be used for,” concludes González de Cosío.

Interested in this story? Want to publish it? Contact our content editor to learn more at marianaleonm@tec.mx.