Eliminating plastic bags is a difficult goal to achieve. Many of us cannot find an equally functional alternative when the time comes to pick up our pets’ feces, for example; tying a knot to a cardboard bag can be complicated. To solve this we have bags created with sustainable plastics.

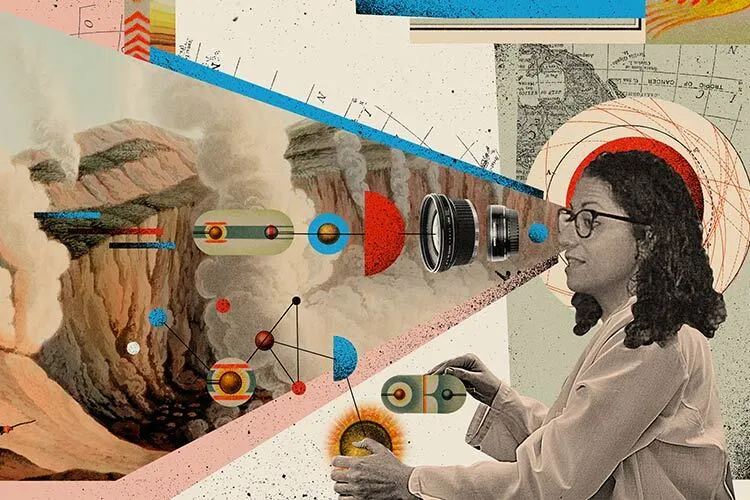

“Once discarded, these degrade in a much shorter period and can serve as fertilizer to nourish plants or the soil,” says Dora Iliana Medina, leader of the Accelerate Materials Development Unit of the Institute of Advanced Materials for Sustainable Manufacturing (IAMSM) from Tec de Monterrey.

The need to find materials that replace traditional plastic is due to the fact that it is created from petroleum, which makes the time it takes to degrade itself very long, with estimates of between 150 and 500 years.

The fact that they are so resistant has resulted in them contaminating the planet’s cities and ecosystems, with aquatic ones being among the most affected.

Animals, wild and domestic, can accidentally consume them, which threatens their lives. “They are lethal to turtles, whales and dolphins because they swallow them or can become entangled in them,” explains Medina.

Microplastics and the toxic emissions that result from burning them are also part of the problem.

Despite this, around 500 billion plastic bags are used in the world each year, according to estimates by the United Nations (UN).

“Many continue to be discarded after a single use,” says the expert.

For this reason, at a global level, measures have been taken to reduce their use, stop their production and replace them with ones made from biodegradable materials.

How to make biodegradable plastic bags

In Mexico, a few years ago, supermarkets had begun to package food with bags that claimed to be biodegradable, however, most did not comply with the necessary regulations.

“Much of the material with which they were made was still petroleum derivatives,” explains Medina.

In response to this, starting in 2021, Mexico City enforced a ban on single-use plastics and disposables.

That is why today, when we go to the supermarket we find cardboard bags instead of plastic bags to transport fruits and vegetables.

However, many of us still find ways to access plastic bags to use to dispose of our organic waste or pick up after our pets.

“Humanity has become very dependent on plastic bags,” says the researcher.

This is due to many factors, but the fact that we consumers prefer them for some specific tasks has a lot to do with it.

For the expert, this is largely due to the properties of bags made with polyethylene, the most common type of plastic used today. It is flexible, resistant, waterproof, light and versatile, making bags made with it very comfortable.

“It is a widely studied material, it is easy to process and, in addition, it is cheap,” explains Medina.

A project that seeks to create a truly biodegradable and sustainable plastic

Finding a material that is just as convenient and accessible as polyethylene is a challenge for those looking to create sustainable plastics.

In the unit led by Medina, in recent years, one of their main projects has been to produce a plastic from plant waste, such as coffee beans, to create bags with properties similar to traditional ones.

To achieve this, they mix polyvinyl alcohol -a water-soluble polymer-, chitosan -a biopolymer- and holocellulose -a specific type of cellulose- extracted from coffee beans.

By mixing the three elements, they obtain a thin film that can be used as an alternative to create truly biodegradable packaging and bags.

“When discarded, it decomposes into its main components, cellulose, which nourishes plants, but also has antioxidant properties that can contribute to soil health,” says Medina.

For the moment, they have managed to verify that the plastic they obtain has a macro and microscopic structure with properties that allow it to repel water, maintaining sufficient firmness and flexibility, so that the bag can be manipulated, but does not break upon contact with any liquid.

In the near future, they plan to start testing this material in bags to see if they are a functional alternative.

If the technology is successful, it could also be applied using organic waste such as avocado peels, orange peels or sugar cane leftovers.

“I think that the fact that waste is our raw material and, furthermore, the plastic we create does not harm the environment is something very positive,” says Medina.

While taking the necessary steps to create a product that is affordable for businesses and scalable at an industrial level, citizens can choose to reduce the use of plastic bags as much as possible and reuse them as much as possible.

Were you interested in this story? Do you want to publish it? Contact our content editor to learn more marianaleonm@tec.mx