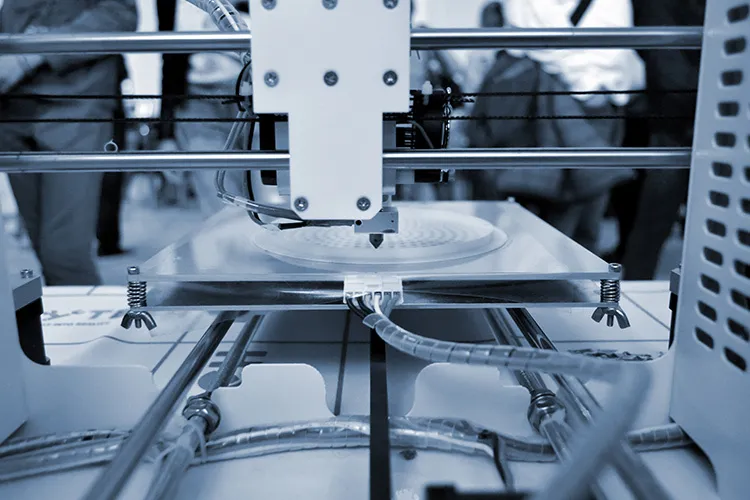

Manufacturing has traditionally involved the mass manufacture of pieces or components that all usually have the same design and specified qualities. However, additive manufacturing is emerging as an industrial revolution that can be more efficient and sustainable.

Unlike traditional manufacturing, additive manufacturing focuses on the progressive addition of material layer by layer for product design and manufacture. This method of producing components is more adaptable and adjustable, while also allowing for the use of less material, resulting in less waste and more sustainable production.

Due to the growing popularity of additive manufacturing, Tec de Monterrey has announced the creation of a Core Lab dedicated to this technology, which will have specialized equipment and staff who will work with people from business and academia.

This specialized laboratory will be inaugurated at the 2nd International Conference on Advanced Materials and Additive Manufacturing, which will take place from September 20 to 22, 2023 at the Technological Research and Innovation Park (PIIT for its initials in Spanish) in Monterrey, Nuevo León.

“The Core Lab’s mission is to support and empower researchers to develop technological advancements and explore new materials and processes,” explains Óscar Martínez, who runs the Additive Manufacturing Core Lab and is a member of Tec de Monterrey’s Institute of Advanced Materials for Sustainable Manufacturing (IAMSM).

2nd International Conference on Advanced Materials and Additive Manufacturing

According to Alex Elías, leader of the Accelerated Materials Development unit at the Institute of Advanced Materials for Sustainable Manufacturing, both the laboratory and the Conference will focus on addressing industry demands, particularly those connected to nearshoring.

“We want to demonstrate to society that we are capable of developing materials, integrating them into a sustainable manufacturing process, and showcasing disruptive technologies,” he adds.

According to Daniel Olvera, an IAMSM researcher, there is a migration of enterprises and changes to the supply chain of industries in the United States that demand more suppliers near their borders.

Alex adds that foreign investment has increased, with 30% of this moving into manufacturing with a concentration on automotive, logistics, hardware development, and medical.

Mexico has caught the interest of countries such as the United States, Japan, Germany, South Korea, and China because of its vital location in delivery to American and Latin American markets. As a result, promoting additive manufacturing has become critical as an approach for further streamlining industrial processes.

According to Elías, the event will include interactive seminars so that corporations and industry leaders can directly experience these technologies and appreciate the value of human resources and teamwork.

“We want to present solutions to the significant challenges posed by relocation and demonstrate to the production chain that we will have the centers to do the work, as well as the technological and scientific capacity,” Elías says.

Additive Manufacturing Core Lab

Large printing machines such as those located in the additive manufacturing Core Lab are used for this kind of production. Some of these were developed by GE Additive, a General Electric company dedicated to this technology.

The Tec purchased equipment from this division in 2023, including the M2 Series 5 and MLab 200R, the latter of which can print reactive materials such as titanium and aluminum.

The Core Lab will also allow students, academics, and businesses to cooperate and exchange expertise on diverse projects.

“Our primary role will be to meet the research and production needs of companies, but we will be open to both academic and industrial worlds,” Óscar Martínez says.

He also stated that IAMSM currently works with companies such as Honeywell Aerospace, which manufactures aircraft components in Mexico.

“Companies can efficiently design, test, and adjust their products. We are now only a click away from providing the components and products they want to create and have been working with aircraft industries to provide them with a technological option.”